Product Description

Product Description

| Wheel Dia | 40mm(1.6”),50mm(2”),63mm(1.6”),75mm(3”),100mm(4”),125mm(5”) |

| Wheel Material | PU, PP, TPR, High-tempature PA, PA, ER, Antic-static TPR |

| Fork Assembly | Dark Green Painted, Zinc Plated, Chrome Plated,Color Galvanized, Dark green Plastic |

| Fitting | Swivel(top plate), Swivel(thread plate), Swivel(hollow rivet), Rigid, Swivel grip ring stem |

| Brake Assy | Total lock brake(metal), Tread lock brake(metal), Side lock brake(metal), Total lock brake(plastic), Tread lock brake(plastic), Total side lock brake(metal) |

| Bearing Model | Singel ball bearing, Double ball bearings, Derlin bearing, Plain bore(bushing bearing) |

| Application | Genreral industry, Trolley, Medical equipment, Electronic equipment and logistics handling, Scaffold, Material shelf |

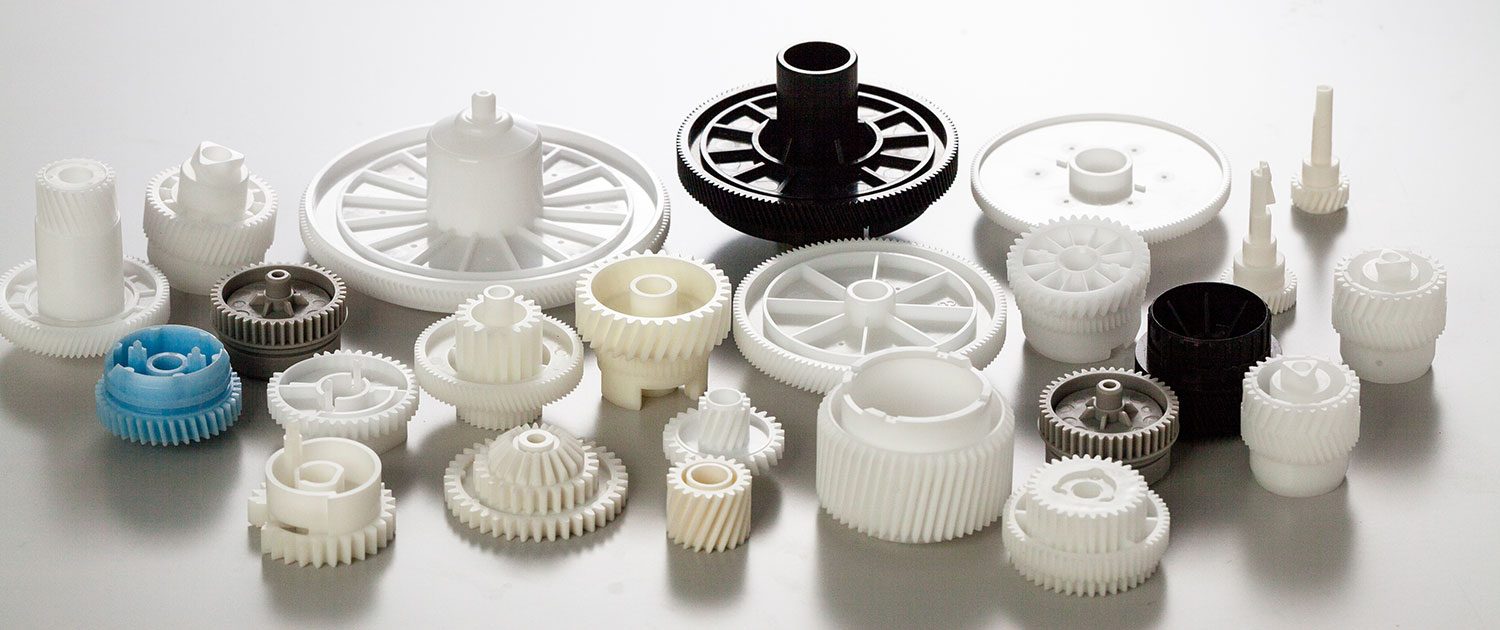

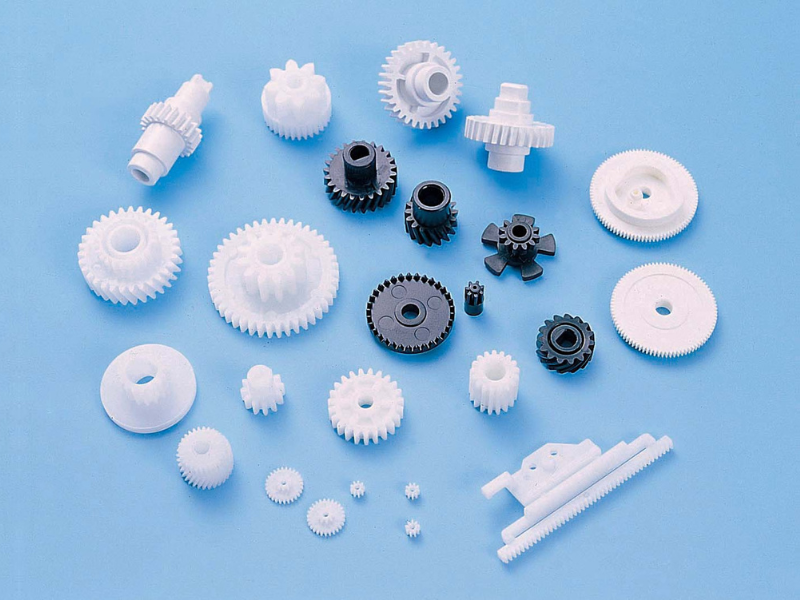

Detailed Photos

Company Profile

Certifications

Our Advantages

Customized Service of SUPO

The approval loading weight in this industry purchase guide, means to satisfy 1. ground smooth 2. environment temperature between 20-30ºC(except for high-temperature caster)3. moving speed would not exceed 4km/h.

1. If single caster chosen by you is over 200kg, traction method as motive power, moving speed does not exceed 6km/h, and satisty other 2 contditions. In order to ensure the life length of caster, please let actual loading weight don’t surpass 80% of approval weight.

2. If single caster chosen by you is over 200kg, traction method as motive power, moving speed does not exceed 6-8km/h,and satisty other 2 contditions. In order to ensure the life length of caster, please let actual loading weight don’t surpass 60% of approval weight.

If the caster of your demand is over above-mentioned conditions, please contact with us. Our professional engineering team will provide customized caster base on your industry’s applied environment and installation dimension.

FAQ

1. Are you trading company or manufacturer?

We are manufacturer since 2004. Previous it was plastics ejection company with over 20 years experience.

2. What is your warranty for your products?

18 months from the producing, the each item showed the producing date.

3. How can you control your quality?

First, we have raw material testing. A.Determing the melt mass flow rate of various thermoplastics. B. Test the mechanical properties of various materials such as tension, compression, bending, shearing, tearing and pelling. C. Making test samples. D. Fast and accurate moisture determination. E. Fast and accurate measurement of CHINAMFG density. F. Determination of the impact strenght of plastics.

Then we have 1+11 testing standard: Weight carry running test

1.Initial wheel hub clearance test

2.Attrite wheel hub clearance test

3.Initial rotation clearance test

4.Attrite rotation clearance test

5.Braking test

6.Wheel brake effectiveness test

7.Rotation braking effectiveness test

8.Vertical static pressure test

9.Salt and acid test

10.High temperature test

11.Low temperature test

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Type: | Rotating Wheel |

|---|---|

| Wheel Material: | PU |

| Brake: | With Brake |

| Bearing Type: | Roller Bearing |

| Surface Treatment: | Zinc Plated |

| Brand: | SUPO |

| Samples: |

US$ 5/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

What advantages do plastic wheels offer in terms of corrosion resistance and longevity?

Plastic wheels offer several advantages in terms of corrosion resistance and longevity, making them a preferred choice in various applications:

- 1. Corrosion Resistance: Plastic wheels are inherently resistant to corrosion. Unlike metal wheels, which can rust or corrode when exposed to moisture or harsh chemicals, plastic wheels do not rust or corrode. This corrosion resistance is especially valuable in wet or corrosive environments.

- 2. Chemical Resistance: Plastic wheels can withstand exposure to a wide range of chemicals, acids, and solvents without deteriorating. This resistance to chemical damage extends their lifespan when used in environments where chemical spills or exposure is a concern, such as in laboratories, manufacturing facilities, or healthcare settings.

- 3. Moisture Resistance: Plastic wheels are not affected by moisture, making them suitable for outdoor applications or environments with high humidity. They do not absorb water, preventing swelling, warping, or degradation due to moisture exposure.

- 4. UV Resistance: Some plastic materials used for wheels are UV-resistant, which means they can withstand prolonged exposure to sunlight without degrading or becoming brittle. This quality is beneficial for outdoor applications, including lawn and garden equipment.

- 5. Longevity: Plastic wheels are designed for durability and a long service life. High-quality plastics, reinforced designs, and proper maintenance contribute to their longevity. They do not suffer from wear and tear like rubber or pneumatic tires and can maintain their performance over extended periods.

- 6. Low Maintenance: Plastic wheels typically require minimal maintenance. They do not need lubrication, and their surfaces are easy to clean. This reduces the need for ongoing maintenance, saving time and resources.

- 7. Lightweight: Plastic wheels are lightweight compared to many metal alternatives. Their reduced weight places less stress on equipment, reducing wear and tear and contributing to their overall longevity.

- 8. Non-Marking: Some plastic wheels are designed to be non-marking, meaning they won’t leave scuff marks or damage flooring surfaces. This feature is valuable in applications where protecting the floor’s appearance is important.

- 9. Floor Protection: Plastic wheels, especially those with softer materials or specialized coatings, provide excellent floor protection. They are gentle on surfaces and do not scratch or dent floors, making them ideal for indoor use.

Overall, the corrosion resistance and longevity of plastic wheels make them an excellent choice for applications where environmental factors, chemicals, or moisture could compromise the performance and lifespan of other wheel materials, such as metal or rubber.

Can you share tips for selecting the right plastic wheels based on specific industry requirements?

Selecting the right plastic wheels based on specific industry requirements is essential for optimal performance and reliability. Here are tips to guide your selection process:

- 1. Identify Load Requirements: Determine the maximum load capacity your plastic wheels need to support. Consider potential variations in load and choose wheels with a suitable load rating to ensure safe operation.

- 2. Evaluate Material Compatibility: Assess the environmental conditions your plastic wheels will encounter. Choose materials that are compatible with the industry’s specific environment, such as chemical resistance for manufacturing or moisture resistance for healthcare settings.

- 3. Consider Temperature Range: If your industry operates in extreme temperatures, select plastic wheels that can withstand the temperature range without deformation or loss of performance.

- 4. Prioritize Floor Protection: In indoor or commercial settings, prioritize wheels that won’t mark or damage flooring surfaces. Non-marking and floor-protective wheels are crucial in environments like hospitality and retail.

- 5. Noise Sensitivity: If noise reduction is a concern, opt for plastic wheels known for their quiet operation. Quiet wheels are ideal for office equipment, libraries, and healthcare environments where noise levels are critical.

- 6. Durability and Longevity: Consider the expected service life of the wheels. High-quality plastic wheels with durable materials and construction will reduce maintenance and replacement costs over time.

- 7. Assess Chemical Resistance: In industries where exposure to chemicals is common, select plastic wheels with excellent chemical resistance. This ensures that the wheels won’t degrade or weaken when exposed to corrosive substances.

- 8. Evaluate Impact Resistance: Industries involving heavy equipment or potential impacts should prioritize plastic wheels that can withstand shock and impact without cracking or breaking.

- 9. Customization: Determine if your industry requires customized wheel specifications, such as specific sizes, load capacities, or tread patterns. Customization ensures that the wheels meet precise industry needs.

- 10. Regulatory Compliance: Some industries have specific regulations or standards for wheel materials and performance. Ensure that your selected plastic wheels comply with these requirements to maintain industry standards.

- 11. Test Performance: Whenever possible, conduct performance tests to evaluate how the plastic wheels perform under actual industry-specific conditions. This real-world testing helps ensure that the chosen wheels meet your requirements.

- 12. Prioritize Safety: In industries where safety is paramount, select wheels that provide stability and reliability. Safety-critical applications should never compromise on wheel quality.

- 13. Consider Weight Reduction: In industries where weight reduction is desirable, opt for lightweight plastic wheels. Reduced weight can improve energy efficiency, especially in applications like aerospace or automotive.

By considering these industry-specific factors and tips, you can make informed decisions when selecting plastic wheels that best meet the requirements of your particular industry. This ensures that your equipment and systems operate efficiently and reliably in their respective environments.

What is a plastic wheel, and how is it different from other types of wheels?

A plastic wheel is a type of wheel that is primarily constructed using plastic materials. It differs from other types of wheels, such as steel or aluminum wheels, in several ways:

- 1. Material Composition: The most significant difference is the material used. Plastic wheels are made from various types of plastics, such as polypropylene, polyurethane, or nylon. In contrast, steel wheels are constructed from metal, and aluminum wheels are made from aluminum alloys.

- 2. Weight: Plastic wheels are generally lighter than their metal counterparts. This reduced weight can be advantageous for applications where weight savings are essential, such as in industries like automotive and aerospace.

- 3. Corrosion Resistance: Plastic wheels are inherently resistant to corrosion, making them suitable for use in wet or corrosive environments. In contrast, metal wheels, especially steel wheels, are susceptible to rust and corrosion over time.

- 4. Cost: Plastic wheels are often more cost-effective to manufacture than metal wheels. This cost advantage can make plastic wheels an attractive option for various applications, including consumer products and industrial equipment.

- 5. Load Capacity: Metal wheels, especially those made from steel, tend to have higher load-carrying capacities compared to plastic wheels. Metal wheels are often used in heavy-duty applications where substantial weight-bearing capacity is required.

- 6. Durability: Metal wheels are generally more durable and have a longer lifespan, especially in high-stress or abrasive environments. Plastic wheels may wear out more quickly when subjected to heavy loads or rough surfaces.

- 7. Noise and Vibration: Plastic wheels can offer noise and vibration dampening properties, which can be advantageous in applications where reducing noise is essential, such as in office chair wheels.

- 8. Heat Resistance: Metal wheels typically have better heat resistance properties compared to plastic wheels. Metal wheels can withstand higher temperatures without deforming or losing structural integrity.

- 9. Aesthetic Options: Metal wheels, particularly aluminum wheels, offer a wide range of aesthetic options and finishes. This makes them popular in automotive and custom wheel applications where appearance matters.

The choice between plastic wheels and other types of wheels depends on the specific requirements of the application. Plastic wheels are often preferred for their lightweight, corrosion resistance, and cost-effectiveness, while metal wheels excel in heavy-duty and high-load applications.

editor by Dream 2024-05-07