Product Description

WBD Caster Manufacturer 20+ years:WBD industrial hand pallet nylon plastic caster wheels with bearing

Product Description

Product Parameters

| ART-NO. | Wheel Diameter | Bearing Hole Diameter | Bearing Type | Load Capacity |

| I018F160MCPA/FP | 160*50mm | 20*50mm | Ball Bearing | 350/250kg |

| I018F180MCPA/FP | 180*50mm | 20*50mm | Ball Bearing | 650/600kg |

| I018F200MCPA/FP | 200*50mm | 20*50mm | Ball Bearing | 1000/950kg |

Characteristics of different material casters

1. PU casters: Whether the casters work indoors or outdoors, they can meet your requirements.

2. TRP casters: They can be used in the situations that require less noise and work quietly, like working in hotels, on medical equipment, on floors, on wooden floors, on tile floors ….

3. Nylon casters and iron casters: The casters are suitable for the places where the ground is uneven or where there are iron scraps on the ground.

4. Rubber casters: The casters are inappropriate under the condition of acid, grease and chemicals.

5. Pneumatic casters: The casters are suitable for light load and the uneven roads .

In order to meet the market demands, we always keep paying attention to improving and developing our products and ourselves. Currently we offer more than 2000 different kinds of high quality casters combinations for almost every applications such as: industrial machine, medical facility, furniture, trolley, shopping cart, hand pallet, scaffolding, shelf and so on.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Type: | Rotating Wheel |

|---|---|

| Wheel Material: | Nylon |

| Brake: | With Brake |

| Bearing Type: | Ball Bearing |

| Surface Treatment: | Nylon |

| Brand: | Wbd |

| Customization: |

Available

|

|

|---|

Can you provide examples of products or machinery that commonly use plastic wheels?

Plastic wheels are used in a wide range of products and machinery across various industries due to their versatility and unique qualities. Here are examples of products and machinery that commonly use plastic wheels:

- 1. Office Furniture: Office chairs often feature plastic caster wheels for smooth and quiet movement on office floors.

- 2. Material Handling Equipment: Hand trucks, dollies, and carts used in warehouses and distribution centers frequently use plastic wheels to transport goods efficiently.

- 3. Lawn and Garden Equipment: Lawnmowers, garden carts, and wheelbarrows are equipped with plastic wheels for easy maneuverability on lawns and uneven terrain.

- 4. Retail and Shopping Carts: Shopping carts in supermarkets and retail stores typically have plastic wheels for easy navigation through aisles.

- 5. Medical Equipment: Hospital beds, medical carts, and mobility aids often incorporate plastic wheels, as they are easy to clean and resist corrosion.

- 6. Aerospace Ground Support: Ground support equipment at airports, including baggage carts and maintenance vehicles, may use plastic wheels for their lightweight properties.

- 7. Food and Beverage Handling: Food service equipment, such as serving trolleys and food processing machinery, often feature plastic wheels due to their resistance to moisture and corrosion.

- 8. Recreational Vehicles (RVs): RV leveling jacks and stabilizers utilize plastic wheels to provide stability and ease of adjustment when parked.

- 9. DIY and Home Improvement Tools: Hand trucks, utility carts, and toolboxes used for DIY and home improvement projects may have plastic wheels for ease of movement.

- 10. Industrial Machinery: Some industrial machines and equipment incorporate plastic wheels to facilitate movement and protect factory floors.

- 11. Conveyor Systems: Conveyor systems in manufacturing and logistics often use plastic wheels to support the movement of goods along production lines.

- 12. Skateboards and Skateboarding Equipment: Skateboard wheels are typically made of plastic, offering various sizes and hardness levels to suit different riding styles.

- 13. Boat Trailer Rollers: Rollers on boat trailers are commonly made of plastic, as they resist corrosion when exposed to water and provide smooth boat launching and retrieval.

- 14. Gate Hardware: Some gate wheels and sliding door systems feature plastic wheels for smooth operation and reduced noise.

These examples demonstrate the widespread use of plastic wheels in diverse applications, emphasizing their adaptability and suitability for various industries and products.

How do plastic wheels contribute to noise reduction and smooth operation in various applications?

Plastic wheels play a significant role in reducing noise and ensuring smooth operation in a wide range of applications across various industries. Their design and material properties contribute to these benefits in the following ways:

- 1. Low Friction: Plastic wheels typically have low friction coefficients when in contact with surfaces. This characteristic minimizes the generation of frictional noise during movement. As a result, plastic wheels roll quietly and smoothly.

- 2. Precision Bearings: Many plastic wheel assemblies feature precision ball bearings or roller bearings. These bearings reduce rotational resistance and provide a smooth, friction-free rotation, further contributing to noise reduction and smooth operation.

- 3. Vibration Dampening: Plastic materials have natural vibration-dampening properties. When used in wheels, they can absorb and dissipate vibrations caused by uneven surfaces, reducing the transmission of vibration-related noise to the surroundings.

- 4. Floor Protection: Plastic wheels are gentle on flooring surfaces. They do not scuff, scratch, or mark floors, which is essential in applications where floor protection and aesthetics are important, such as in homes, offices, and healthcare facilities.

- 5. Absence of Metal-to-Metal Contact: Unlike metal wheels, plastic wheels do not produce noise through metal-to-metal contact with surfaces. This lack of contact noise makes plastic wheels quieter and more suitable for noise-sensitive environments.

- 6. Lightweight Construction: Plastic wheels are often lighter than metal alternatives. Their reduced weight places less stress on equipment, resulting in less noise generated by impacts or vibrations when wheels encounter obstacles or uneven terrain.

- 7. Non-Marking Materials: Some plastic wheels are designed with non-marking materials that prevent them from leaving marks or streaks on floors. This feature is valuable in applications where maintaining a clean and unblemished appearance is a priority.

- 8. Custom Tread Design: Plastic wheels can have customized tread patterns that optimize grip and reduce noise. Treads with unique designs can minimize rolling resistance, improve traction, and contribute to quieter operation.

- 9. Moisture Resistance: Plastic wheels do not absorb moisture, which can affect the performance of certain materials like rubber. This moisture resistance ensures consistent operation even in damp conditions.

- 10. Versatility: Plastic wheels are versatile and can be tailored to specific applications. By selecting the right plastic material, bearing type, and tread design, manufacturers can optimize plastic wheels for noise reduction and smooth operation in a variety of settings.

Overall, the noise reduction and smooth operation provided by plastic wheels make them suitable for applications where minimizing noise pollution, ensuring comfort, and maintaining floor integrity are essential considerations.

What is a plastic wheel, and how is it different from other types of wheels?

A plastic wheel is a type of wheel that is primarily constructed using plastic materials. It differs from other types of wheels, such as steel or aluminum wheels, in several ways:

- 1. Material Composition: The most significant difference is the material used. Plastic wheels are made from various types of plastics, such as polypropylene, polyurethane, or nylon. In contrast, steel wheels are constructed from metal, and aluminum wheels are made from aluminum alloys.

- 2. Weight: Plastic wheels are generally lighter than their metal counterparts. This reduced weight can be advantageous for applications where weight savings are essential, such as in industries like automotive and aerospace.

- 3. Corrosion Resistance: Plastic wheels are inherently resistant to corrosion, making them suitable for use in wet or corrosive environments. In contrast, metal wheels, especially steel wheels, are susceptible to rust and corrosion over time.

- 4. Cost: Plastic wheels are often more cost-effective to manufacture than metal wheels. This cost advantage can make plastic wheels an attractive option for various applications, including consumer products and industrial equipment.

- 5. Load Capacity: Metal wheels, especially those made from steel, tend to have higher load-carrying capacities compared to plastic wheels. Metal wheels are often used in heavy-duty applications where substantial weight-bearing capacity is required.

- 6. Durability: Metal wheels are generally more durable and have a longer lifespan, especially in high-stress or abrasive environments. Plastic wheels may wear out more quickly when subjected to heavy loads or rough surfaces.

- 7. Noise and Vibration: Plastic wheels can offer noise and vibration dampening properties, which can be advantageous in applications where reducing noise is essential, such as in office chair wheels.

- 8. Heat Resistance: Metal wheels typically have better heat resistance properties compared to plastic wheels. Metal wheels can withstand higher temperatures without deforming or losing structural integrity.

- 9. Aesthetic Options: Metal wheels, particularly aluminum wheels, offer a wide range of aesthetic options and finishes. This makes them popular in automotive and custom wheel applications where appearance matters.

The choice between plastic wheels and other types of wheels depends on the specific requirements of the application. Plastic wheels are often preferred for their lightweight, corrosion resistance, and cost-effectiveness, while metal wheels excel in heavy-duty and high-load applications.

editor by Dream 2024-05-07

China high quality Durable Plastic Bearing Bag Wheels Soft Fabric Luggage Wheels

Product Description

Certifications

FAQ

Q1: Are you a trading company or manufacturer ?

A1: We are a manufacturer with more than 500 employees and our own sales department.

Q2:What is your company’s way of customization?

1.New product development and design: a new idea of customers, from our drawing design to 3D modeling, mold design, mold production, finished product sample, etc., one- stop to complete the design and development to mass production.

2. Personalized customization:( Based on the company’s mature plan of 20,000 sets, the size, section number, color, LOGO can be customized, free of mold cost,) fast customization. New products customized in any way can be free to use more than 160 patents of the company, all through the professional equipment of the whole project testing, to ensure quality.

Q3:Is the mold of your company also designed and processed by yourself?

A3:Yes, there are 16 R&D and design engineers with more than 10 years of experience in the mold department of our company, who can independently complete the process from mold design to mold making.

Q4: How long is your delivery time ?

A4: Generally, it is 5-10 days if the goods are in stock; or it needs 25-35 days if it’s out of stock.It depends on the quantity.

Q5: Do you provide samples ? Is it free or extra ?

A5: Yes, we could offer the sample for free charge with 2pc/item, but do not pay the freight.

Q6: What’s your terms of payment ?

A6: Payment=2000USD, 30% T/T in advance, 70% balance before shipment.

Q7: Could you please tell me which parts your company mainly produces?

A: Our products are mainly divided into 3 categories:

1. Luggage accessories: trolley handle, universal wheel,caster, grip handle, lock, plastic buckle, hardware etc…

2. Aluminum products: aluminum extrusion, aluminum profile, Welding frame etc…

Q8:Is your company’s mold also designed and processed by yourself?

A:Yes, there are 16 R&D and design engineers with more than 10 years of experience in the mold department of our company, who can independently complete the process from mold design to mold making.

Q9:What is the tonnage of your injection molding machine?

A:Our company has 58 injection molding machines ranging from 80 tonnage to 1500 tonnage with the maximum injection size of 150CM

Q10:What are the main materials of your products?

A:The main materials of our products are ABS engineering plastic PP TPU PE aluminum magnesium pipe zinc alloy etc.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Max Load Capactiy: | 25KG |

|---|---|

| Bearing Type: | Ball Bearing |

| Brake: | Without Brake |

| Wheel Material: | Plastic |

| Type: | Fixed Wheel |

| Sample: | Support Free Samples |

| Samples: |

US$ 1.5/Pair

1 Pair(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

How do plastic wheels fare in terms of weight-bearing capacity compared to other materials?

Plastic wheels have weight-bearing capacity that varies depending on factors such as the type of plastic used and the wheel’s design. Compared to other materials like metal, here’s how plastic wheels generally fare in terms of weight-bearing capacity:

- 1. Light to Medium Loads: Plastic wheels are well-suited for light to medium loads. They can typically support loads ranging from a few pounds up to several hundred pounds, depending on their design and construction. For applications such as office chairs, hand trucks, and smaller carts, plastic wheels are often sufficient.

- 2. Heavy-Duty Loads: When it comes to heavy-duty loads, metal wheels, particularly steel and cast iron wheels, are preferred. Metal wheels can handle much heavier loads compared to plastic wheels. In industrial settings, where loads can exceed a thousand pounds or more, metal wheels provide the necessary strength and durability.

- 3. Load Distribution: Plastic wheels may perform well in load distribution when used in sets or pairs. Distributing the load across multiple plastic wheels can increase their effective weight-bearing capacity. However, metal wheels still excel in heavy load-bearing scenarios.

- 4. Reinforced Plastic Wheels: Some plastic wheels are designed with reinforced materials, internal structures, or additional support to enhance their weight-bearing capacity. These reinforced plastic wheels can handle heavier loads than standard plastic wheels but may not match the load capacity of metal wheels.

- 5. Material and Design: The choice of plastic material and the wheel’s design significantly impact its load capacity. High-quality plastics like nylon and polyurethane tend to have better load-bearing capabilities compared to softer plastics like polypropylene. Additionally, factors such as wheel diameter and tread design play a role in load-bearing capacity.

- 6. Application Considerations: The suitability of plastic wheels for weight-bearing also depends on the specific application. For applications where load capacity is a critical factor, such as heavy machinery or industrial equipment, metal wheels are typically chosen to ensure safety and reliability.

In summary, plastic wheels are suitable for light to medium loads in various applications. They offer benefits such as corrosion resistance, quiet operation, and floor protection. However, for heavy-duty applications with substantial loads, metal wheels, particularly steel and cast iron wheels, are preferred due to their superior weight-bearing capacity and durability.

Are there innovations or advancements in plastic wheel technology that have emerged recently?

Yes, there have been several recent innovations and advancements in plastic wheel technology, driven by the need for improved performance, sustainability, and versatility in various applications. Some notable innovations include:

- 1. Sustainable Materials: Manufacturers are increasingly focusing on using recycled and sustainable plastics to make wheels. These eco-friendly materials reduce environmental impact and align with sustainability goals.

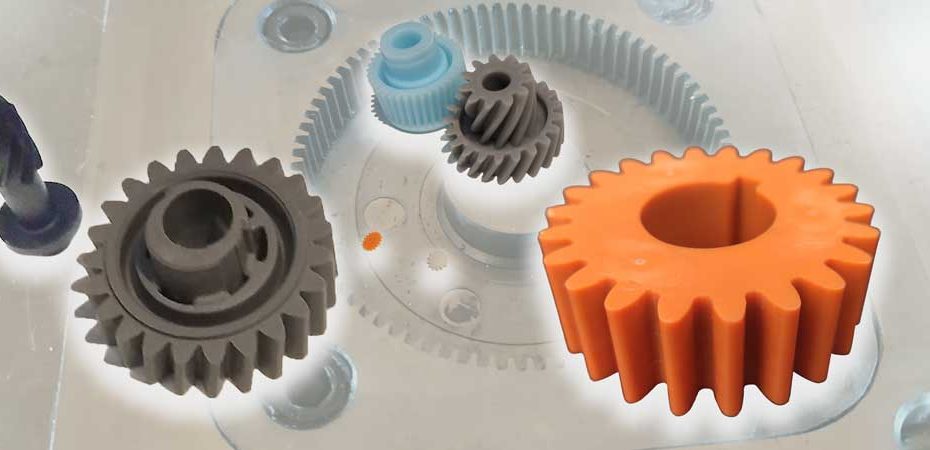

- 2. Reinforced Composites: Advancements in composite materials have led to the development of reinforced plastic wheels with enhanced strength and load-bearing capacity. These wheels can compete with metal alternatives in heavy-duty applications.

- 3. Noise Reduction Design: Innovative tread patterns and materials are designed to further reduce noise and vibration in plastic wheels. This is crucial for applications where noise reduction is a priority, such as in office furniture and healthcare equipment.

- 4. Hybrid Wheels: Some recent designs incorporate a combination of plastic and rubber or other materials to optimize performance. These hybrid wheels offer benefits like improved traction, shock absorption, and load capacity.

- 5. Smart Wheels: Emerging technologies are enabling the development of smart wheels equipped with sensors and data-tracking capabilities. These wheels can provide real-time information about load weight, temperature, and wear, enhancing equipment monitoring and maintenance.

- 6. Antimicrobial Properties: In response to increased awareness of hygiene and sanitation, some plastic wheels are now designed with antimicrobial properties to inhibit the growth of bacteria and germs. This is especially relevant in medical and food service equipment.

- 7. 3D Printing: 3D printing technology allows for the rapid prototyping and customization of plastic wheels. Manufacturers can quickly create intricate designs and tailor wheels to specific customer needs.

- 8. Improved Bearing Systems: Advances in bearing technology have led to the development of high-performance, low-friction bearings for plastic wheels, resulting in smoother and more efficient operation.

- 9. Increased Load Capacity: Through innovative engineering and materials, plastic wheels are now capable of handling heavier loads than ever before, expanding their applications in industries like logistics and manufacturing.

- 10. Enhanced Durability: Recent developments have focused on improving the durability of plastic wheels, increasing their resistance to wear, impact, and environmental factors.

These innovations are driving the adoption of plastic wheels in a broader range of applications and industries, making them a competitive choice alongside traditional wheel materials like metal or rubber.

What are the different types and sizes of plastic wheels available in the market?

The market offers a variety of plastic wheels, each designed for specific applications and available in various sizes. Here are different types and sizes of plastic wheels commonly available:

- 1. Caster Wheels: Caster wheels are used for mobility and swiveling in a wide range of applications. They come in sizes ranging from small, furniture casters to large, heavy-duty industrial casters.

- 2. Hand Truck Wheels: These wheels are commonly used on hand trucks and dollies for moving heavy loads. They are available in sizes such as 8-inch, 10-inch, and 12-inch diameters.

- 3. Trolley Wheels: Trolley wheels are used on material handling carts and trolleys. They come in various sizes, including 4-inch, 5-inch, and 6-inch diameters.

- 4. Lawnmower Wheels: These wheels are designed for lawnmowers and other outdoor equipment. They are available in sizes like 8-inch, 10-inch, and 12-inch diameters.

- 5. Office Chair Casters: Office chair casters come in different sizes to fit various chair bases. Common sizes include 2-inch, 2.5-inch, and 3-inch diameters.

- 6. Heavy-Duty Industrial Wheels: These wheels are used in industrial and manufacturing settings. They are available in larger sizes, such as 6 inches, 8 inches, and even up to 12 inches or more in diameter.

- 7. Skateboard Wheels: Plastic skateboard wheels come in various sizes, typically ranging from 50mm to 60mm in diameter, with different hardness levels for different riding styles.

- 8. Conveyor Wheels: Conveyor wheels are used in material handling and conveyor systems. They come in sizes suitable for specific conveyor designs and loads.

- 9. V-Groove Wheels: V-groove wheels are designed for use on tracks or grooves. They come in sizes suitable for different track profiles and load capacities.

- 10. Trailer Jack Wheels: Trailer jack wheels are used for trailer jacks and stabilizers. They come in sizes such as 6-inch, 8-inch, and 10-inch diameters.

- 11. Light-Duty Wheels: These wheels are used in various light-duty applications, such as small carts and furniture. They are available in sizes ranging from 1 inch to 6 inches in diameter.

- 12. Specialized Wheels: Some plastic wheels are designed for specific applications, such as luggage wheels, boat trailer rollers, and gate wheels. Their sizes vary depending on the intended use.

The availability of plastic wheels in different types and sizes allows them to cater to a wide range of industries and applications. When selecting a plastic wheel, it’s essential to consider factors like load capacity, wheel diameter, tread design, and material to ensure it meets the requirements of the specific use case.

editor by Dream 2024-04-22

China high quality CNC machining factory custom bearing plastic nylon POM bushing near me manufacturer

Applicable Industries: Developing Materials Retailers, Producing Plant, Machinery Repair Outlets, mechanical indusrtial, vehicle industrial

Materials: Customized

Merchandise title: bushing

Processing: CNC machining turning

Certificate: TS16949:2016

Services: OEM, ODM

Sample guide time: 5 days

Tolerance: +/-.01mm

Surface remedy: OEM Made

High quality management: one hundred% Inspection Berore Shipment

Dimensions: Customzied

Packaging Details: 1.Inside of cartons: Plastic bag, air cushion film, sponge, vacuum pack plastic bag, CZPT 6mm planetary steel gearbox gear box for rc drone rust prevented bag,internet bag,plastic tray. 2. Outside cartons: merchandise label, ROHS compliant lable, temperature and humidity control label if necessary. 3.Pallets or wooden cases. Or according to customers’ demands

Port: HangZhou

Firm PROFILE(1)

OUR Equipment:

MEASURING Instruments:

Production & QC Movement:

Client Responses:

Related Products:

Packing & Shipping:

FAQ:

1. What is actually your advantage?

– We are a direct manufacturer

-Often becoming Trustworthy, Professional and Proactive.

-More than twenty a long time in the CNC precision machining business.

–Japan Tsugami CNC equipment, Planetary Equipment Established Box Differential Planetary Reduction Gearbox Transmission Producer with slicing edge CNC answer.

–ISO9001:2015 and IATF16949:2016 High quality handle program, we not only supply competent items, but also care about excellent searching area.

two. Which languages do you use for interaction.

Traveling to EU international locations, United states,Japan and Australia 2 to 3 times a calendar year, our worldwide product sales crew speak English, Japanese and Russian.

three. When will I get the estimate and info?

Our group will report inside of 12 hrs.

4. What if I never have a drawing?

Please deliver us pictures to check out, and the sample, Wonderful Space Business Ltd CZPT 6d16 pto equipment box electricity consider off gearbox we will make a drawing in CAD,Proe,UG or Solidworks structure for your approval.

5. How prolonged will I get your samples?

Depends on substance and design and style, 5 to 10 days.

6.What is actually your minumum get amount(MOQ)?

one piece, small buy portions are welcome.

7.How do you care about the logistic?

We function very carefully with the logistic brokers,constantly to get the

most risk-free and inexpensive resolution regarding convey shipping, air shipment or sea shipment.

eight. If you make areas wrong, do you refund funds?

If the areas are improper, Cycloid gear reducer for bathroom tissue recycle paper pulp gearbox reduction for paper creating device we will return your funds or we can make right areas to you once again.

Contact window:

Phone/Wechat: 185 6657 1980Skype:amy.ho.jinboWeb:

Bushing Software, Sort and Compression Functionality

Bushings are cylindrical bushings employed in machinery. It stops use of relocating parts and is usually used as an enclosure. Bushings are also identified as plain bearings or sleeve bearings. You may possibly be questioning what these parts do and how they work, but this write-up aims to reply all your inquiries. We are going to go over bushing purposes, sorts and compression abilities so you can pick the right 1 for your requirements.

application

A bushing is a mechanical component that plays an essential part in a lot of diverse fields. In addition to being very useful, it aids minimize sound, vibration, dress in and supplies anti-corrosion homes. These qualities assist mechanical products in a variety of approaches, which includes producing it simpler to keep and reducing its all round framework. The functionality of an enclosure relies upon on its goal and setting. This write-up will go over some of the most typical apps of casing.

For instance, in an aircraft, the bushing assembly sixteen may be utilized for the bulkhead isolator forty . The bushing assembly 16 provides the interfaces and paths needed for existing circulation. In this fashion, the sleeve assembly supplies a protected, dependable relationship among two objects with diverse electrical charges. They also avoid sparking by increasing the electrical conductivity of the part and decreasing its resistivity, therefore minimizing the opportunity of spark development.

An additional frequent software for bushings is as a assist shaft. Not like bearings, bushings run by sliding between two shifting surfaces. As a end result, they lessen friction and managing pressure, reducing overall maintenance charges. Generally, the bushing is made of brass or bronze. The advantages of bushings are equivalent to people of bearings. They support prolong the lifestyle of rotating devices by minimizing frictional strength reduction and dress in.

In addition to pinpointing development chances and reducing pitfalls, the Bushing Anti-Vibration Mounts Market place report gives insights into the dynamics of the market and its crucial players. The report addresses global marketplace dimension, programs, expansion prospective customers, issues and regional forecasts. The detailed part on Bushing Anti-Vibration Mounts industry offers insights on desire and source along with aggressive evaluation at regional and country amount.

type

There are a number of varieties of bushings. Amongst them, the SF6 insulating sleeve has the most straightforward construction and is based on composite hollow insulators. It also has several metallic shielding cylinders for regulating the electrical discipline within the enclosure and yet another for grounding the metal defend. In addition to getting light-weight, this sleeve is also really tough, but the diameter of its shield electrode is extremely large, which means unique set up and handling methods are essential.

Linear bushings are generally pressed into the bore of the shaft and supply assistance as the shaft moves in/out. Non-push-fit bushings are held in location by snap rings or pins. For particular apps, engineers typically select bushings over bearings and vice versa. That is why. Underneath are some typical bushing sorts. If you want to buy, make certain you know how to inform them aside.

OIP bushings are utilized for oil-crammed cable packing containers, and oil-to-oil bushings are used for EHV electrical power transformers. The primary components of the OIP enclosure are demonstrated in Determine 7a. If you are taking into consideration this sort of bushing for your certain software, you require to make positive you understand your certain needs. You can also seek the advice of your regional engineering division for much more information.

All kinds of bushings ought to be tested for IR and capacitance. The take a look at faucet must be securely attached to the bushing flange. If ruined bushings are identified, replace them right away. Be certain to keep full documents of the enclosure for schedule maintenance and any IR testing. Also, be confident to pay out interest to tan d and thermal vision measurements.

Compressive capacity

There are a number of issues to contemplate when deciding on an enclosure. First, the material. There are two main varieties of bushings: people created of stuffed Teflon and these manufactured of polyester resin. The former has the greatest compressive toughness, although the latter has a decrease compressive potential. If you need to have modest amounts, glass-stuffed nylon bushings are the most typical and best option. Glass-stuffed nylon is an inexpensive material with a compressive toughness of 36,000 lbs.

2nd, the materials utilised for the enclosure should be ready to withstand the load. For illustration, bronze bushings can cause steel shavings to drop into the papermaking procedure. CG materials can face up to really large levels of humidity, which can harm bushings that call for lubrication. Additionally, these resources can run for extended intervals of time without having lubrication. This is particularly useful in the paper industry, since the casing operates in a humid environment.

In addition to the material and its composition, other qualities of the enclosure need to also be regarded as, like its operating temperature. Although frictional warmth from moving masses and the temperature of the bushing itself can impact the efficiency of the bushing, these factors decide its service life. For large temperature purposes, the PV of the enclosure need to be held low. On the other hand, plastic bushings are normally much less heat resistant than metal bushings. In addition, plastic sleeves have a large price of thermal expansion. To keep away from this, dimensions management is also critical.

Minimal pressure bushings have diverse requirements. An 800 MVA installation needs a minimal voltage bushing rated at fourteen 000 A. The palm assembly of the transformer also attributes a big central copper cylinder for electrical existing. The bushing need to face up to this volume of existing and must keep an even distribution of existing in the transformer tank. If there is a leak, the bushing have to be able to resist the leak so as not to injury the transformer.

price

The expense of new control arm bushings varies extensively. Some parts are less costly than others, and a new portion is only $two hundred. Nevertheless, if you substitute the 4 handle bushings in your automobile, the value can exceed $1,200. The expense breakdown for each segment is listed beneath. If you strategy to exchange all 4, the expense of each bushing could selection from $200 to $five hundred.

The management arm bushing bears the brunt of the forces produced by the tire and is parallel to the path of the power. Nevertheless, over time, these factors dress in out and want to be changed. Changing a single manage arm bushing expenses between $three hundred and $1,200. Nevertheless, the expense of changing every arm bushing is dependent on your vehicle product and driving behavior. The handle arm bushings need to previous about one hundred,000 miles ahead of needing alternative.

The repair approach for manage arm bushings is time consuming and pricey. Also, they may need to take away the warmth protect or bracket. In possibly scenario, the procedure is simple. Stabilizer bar brackets are usually attached with a single or two mounting bolts. They can also be secured with nuts or threaded holes. All you need to have is a wrench to take away them.

The handle arm bushings are produced of two steel cylinders and a thick rubber bushing. These areas can deteriorate from potholes, off-roading or accidents. Because they are created of rubber, the parts are far more pricey than new. Buying utilised kinds can help save you income because you do not want to install them by yourself. Nevertheless, if you do plan on repairing a luxurious vehicle by yourself, be positive to find one particular that has a guarantee and warranty.

sustain

To prevent your vehicle from overheating and leaking oil, a properly performing bushing must be employed. If the oil amount is too lower, you will require to check out the mounting bolts to make positive they are properly tightened. Check gasket to ensure suitable compression is utilized, exchange bushing if essential. You should notify your automobile manufacturer if your vehicle is immersed in oil. Each time an oil leak happens, it is very crucial to change the oil-filled bushing.

An additional crucial element of bushing servicing is the detection and correction of partial discharges. Partial discharge is induced by existing getting into the bushing. Partial discharge can lead to tree-like structures, cracks and carbonization in the discharge channel, which can sooner or later injury the casing. Early detection of these procedures is essential to making sure that your vehicle’s bushings are correctly maintained. Determining and repairing partial discharges is vital to ensuring optimal operation, irrespective of the sort of pump or motor.

To diagnose casing condition, perform many exams. You can use tan d measurement, which is a effective tool for detecting the ingress of h2o and humidity. You can also use power aspect measurements to detect localized defects and aging effects. You can also check out the oil degree by carrying out an infrared examine. After completing these checks, you will be capable to decide if there is adequate oil in the casing.

If the oil amount in the transformer is too minimal, water and air may possibly leak into the transformer. To keep away from this dilemma, be sure to examine the MOG and transformer oil ranges. If the silicone is pink, replace it. You must also check out the purpose of the oil pump, admirer and control circuits yearly. Verify the physical problem of the pump and fan and whether they want to be changed. Cleanse the transformer bushing with a delicate cotton cloth and inspect for cracks.

China wholesaler 657550mm Oilless CZPT Collar Bronze bush with Non-Liquid Lubricant, ZW13 oilless CZPT bushing, graphite bearing with high quality

Applicable Industries: Building Content Outlets, Producing Plant, Machinery Mend Retailers, Meals & Beverage Manufacturing unit, Farms, Retail, Printing Outlets, Design works , Energy & Mining

Design Amount: 65*seventy five*50mm

Variety: sleeve, Graphite bearing

Materials: brass, CuZn25Al5,C86300,SAE 430B

Size: sixty five*seventy five*50mm

Hardness: >210

Application: Automotive Mould, Outstanding good quality RV050 collection worm equipment reducer appropriate angle gearbox electric trolling motor foot mounted worm gearbox Plastic business

Specification: Standard measurement and customized

Lubricant: graphite, SL1, SL4

Bush varieties: Cylinder, Collar, Thrust Waser, plates

Certification: ISO 9001:2008

Attributes: Self lubricating, Routine maintenance free

Graphite bearing definitionOil-cost-free sliding bearings can be self-lubricated by layout, operate efficiently, reliably and without having noise. Under the issue of liquid lubrication, the sliding area is divided by lubricating oil with out immediate get in touch with, and the friction decline and surface area wear can be significantly lowered. Advantage1. CZPT to Carry Higher Loads 2. With a Substantial Load-Bearing Capacity3. Minimal Noise and Much more Quiet4. Long Lifestyle,Stable Overall performance and Durable 5. Have Low Rolling Resistance and Operate in Sub-Zero Temperatures Product Identify Graphite bearing sixty five*seventy five*50mmTypeself lubricating bearingMaterialChrome SteelCharacteristicEasy to change and install, properly sealed, Large top quality ac motor with nmrv50 gearbox suitable for higher dust setting, multiple repairing methods are optional, and multipledesigns are utilised.Supply time5-7 days,Related by order quantityApplicationThe sliding bearing has the benefits of simple framework, convenient production, little radial dimensions, sturdy vibrationabsorption capacity of the vital oil film, etc. Employs of Graphite bearingone. Shaft sleeve and pin sleeve for joint components of design machinery (excavator, bulldozer, loader).2. Hefty-obligation automobile balance shaft bushings.3. Shock absorber bushes for autos and bikes.4. Hydraulic business, hydraulic gear pump bushings, oil cylinders, cylinder bushings, Earth Gearbox etc.5. Injection molding equipment, vulcanizing device.6. Mildew industry, plastic mould, auto mildew CZPT sleeve7. Water turbine turbine of h2o conservancy equipment.8. Forging sector, punching machine, and many others.9. Metallurgical market.

* Generation processes Semi-Computerized PET Bottle Blowing Device Bottle Making Device Bottle Moulding Machine PET Bottle Creating Device is appropriate for generating PET plastic containers and bottles in all designs. This is a photo of our participation in the exhibition and the go to of the buyer to the manufacturing unit. Our employees took element inthe CZPT assembly and climbed the mountain to do volunteer pictures. Associated Products Comprehensive Images During the customer’s get manufacturing process, we have out processing inspection, the purpose is to do much better quality handle Semi-Computerized PET Bottle Blowing Equipment Bottle Generating Device Bottle Moulding Device PET Bottle Generating Equipment is ideal forproducing PET plastic containers and bottles in all designs. Packing&Shipping and delivery Semi-Computerized PET Bottle Blowing Equipment Bottle Making Device Bottle Moulding MachinePET Bottle Producing Device is ideal for making PET plastic containers and bottles in all shapes. Business Introduction Sheng Yao Wang (HangZhou) International Trade Co., LTD. has been focusing organization of bearing creation and trade for 17 a long time, has prosperous encounters in bearing processing and trade, to give clients with skilled bearing application remedies. The companyprovides the customized items and OEM service. Different new collections and layout are coming out every thirty day period with the currentstyles and materials. The manufacturing facility own the proficient talent and current machine The consumer evaluationWe are really happy that the client can give us large praise, ZheJiang CZPT KA87 helical bevel gearbox we carry on to provide the client satisfaction for the purpose FAQ Our customersWe are a large household, not only colleagues, but also buddies. We think that friendship is the most critical issueThe Advantages of Making use of Self-Lubricating Bushings for Your Following Pivot

Like any other automobile component, management arm bushings dress in out above time. This final results in an enhance in annoying vibrations that can be dangerous in extreme instances. The bushings in the management arms also dress in out due to the pressure that extreme driving conditions put on the manage arms. Additionally, environmental variables and oversized tires are likely to transmit much more vibration through the bushing than conventionally sized tires. Whatever the lead to, bushings can be the resource of many problems.

use and cracking

The main lead to of dry valve facet bushing cracking is a mismatch in thermal expansion of the main and flange. This situation can seriously compromise the protection of the power method. To enhance the security of dry valve facet bushings, the crack development of epoxy impregnated paper beneath various problems was investigated. A coupled thermomechanical simulation product was also employed to study the cracking approach.

The 1st stage in diagnosing the trigger of bushing dress in and cracking is a visible inspection. The bushing of the lower handle arm is mounted to the body by a bracket. If there are any seen cracks, it’s time to change the bushing. Nevertheless, there is no need to substitute the whole suspension. In some cases, worn bushings can cause a range of troubles, including entire body lean, abnormal tire put on and cornering sound.

Servicing free of charge

If you are contemplating servicing-free of charge bushings for your next pivot, you’ll be pondering what to seem for in these elements. The bushing guards the housing from corrosion and keeps the bushing beneath stress. Even so, several consumers are not acquainted with what these parts can do for their applications. In this post, we’ll appear at several illustrations of truly servicing-cost-free pivots and examine their needs.

One particular of the most well-liked sorts of upkeep-cost-free bushings are flanged and parallel. Not like worm gear bushings, these self-lubricating steel bearings are perfect for a variety of apps and conditions. They reduce failure and downtime charges whilst delivering the long-time period lubrication required by other sorts of bushings. Since these sleeves are manufactured of direct-cost-free materials, they are RoHS compliant, which means they are environmentally pleasant.One more frequent servicing-free bushing is plastic. This materials is less difficult to uncover off-the-shelf and comparatively low-cost to create. However, it is not suitable for higher load applications as it will crack beneath weighty hundreds and injury mating parts. Plastics can also deviate if the producing method is imprecise. Plastic bushings can also crack when subjected to high hundreds.

self-lubricating

When using a self-lubricating bushing, there is no want to apply grease to the bushing. Oily liquids tend to entice dirt and grit, which can use absent the graphite prematurely. By eliminating the need for standard lubrication, you will reduce tools maintenance expenses. This post will discover the rewards of self-lubricating bushings. You will love your kindness.

Self-lubricating bushings have a powerful foundation materials to face up to radial bearing strain even though offering shaft help at the make contact with surfaces. The material also has excellent fatigue houses and reduced friction motion. Self-lubricating bushings can be utilised in environments with large temperatures and intense media. These products can also endure massive strain. When using self-lubricating bushings, it is essential to choose the appropriate substance.

The main advantage of utilizing self-lubricating bushings is ease of maintenance. They don’t call for oil to operate and are less costly to acquire. Their major reward is that they can substantially reduce your machine operating expenses. These bearings do not need oiling functions, lowering servicing expenses. These bearings also supply a simplified mechanical layout because of to their slender partitions and high load ability. In addition, they decrease sound stages although sustaining superb put on resistance. Plus, their resources are ROHS compliant, which indicates they never require oil.

Hydropower installations are an additional region in which self-lubricating bushings have established their advantages. They minimize routine maintenance costs, extend equipment daily life, and improve environmental benefits. For illustration, the Newfoundland Power Organization utilizes self-lubricating bushings in the gates of its hydroelectric electrical power vegetation. These self-lubricating bushings eliminate grease from moving into waterways and tailraces. As a end result, power organizations are capable to minimize servicing and fees.

compared to cartilage in the human human body

What is the distinction amongst tendon, bone and cartilage? Human cartilage is composed of collagen and elastic fibers. In contrast, fibrocartilage is made up of far more collagen than hyaline cartilage. Both cartilage kinds are composed of proteoglycans, which have a protein backbone and glycosaminoglycan facet chains. These parts work together to offer construction and overall flexibility to the cartilage.

Bone is a blend of living and lifeless cells embedded in a matrix. The outer difficult layer of bone is dense bone, and the inner layer is spongy, made up of bone marrow, blood vessels, nerves, and many others. Bone includes the two natural and organic and inorganic substances, and this approach of hardening of the matrix produces bone. On the other hand, cartilage consists of chondrocytes and a matrix composed of collagen and elastin fibers. In comparison to bone, cartilage is yellow and contains elastic fibers.

Even though bone and cartilage are structurally similar, cartilage is more flexible. It is primarily discovered in the joints and respiratory system and calls for versatility. Its components incorporate collagen and proteoglycans, which give compression and abrasion resistance. Furthermore, connective tissue is composed of cells, fibers and matrix.

The simple substance of cartilage is chondroitin sulfate, which is derived from animals. Though cartilage grows a lot more gradually than bone, its microstructure is significantly less structured. There is a fibrous sheath covering the cartilage, known as the perichondrium. The molecular composition of the ECM plays an critical function in the purpose of cartilage. The collagen matrix is important for cartilage reworking and is made up of modifications in the collagen matrix.

When compared to steel-on-bone get in touch with

Both metallic-on-bone get in touch with are recognized to trigger a important improve in the pressures in a joint. To evaluate the two, we first calculated the joint speak to pressures in every single design and in comparison them. The results of this study help prior analysis on this subject matter. The following sections go over the benefits of equally varieties of contact. They also define some important distinctions amongst the two.