Product Description

Product Description

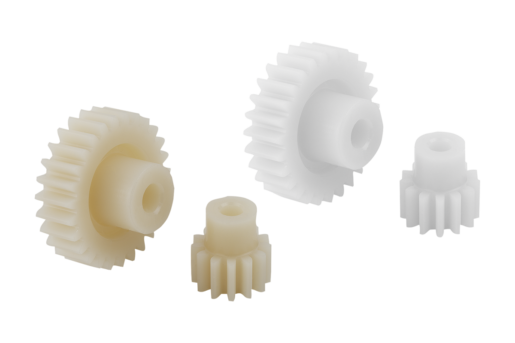

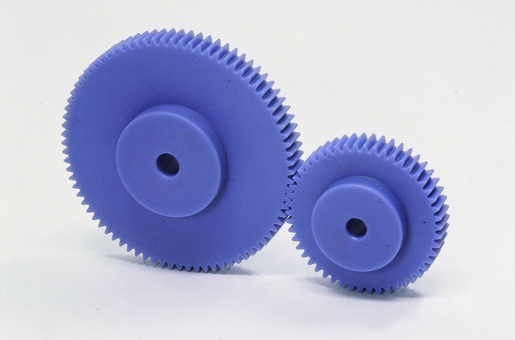

Machine Drive Involute Transmission Precision Injection Plastic helical cylindrical Worm Gear Wheel

| Item | Customized Injection and machining gears | |

| Process | Injection molding,CNC machining, | |

| material | Nylon, PA66, NYLON , ABS, PP,PC,PE,POM,PVC,PU,TPR,TPE,TPU,PA,PET,HDPE,PMMA etc | |

| Quality Control | ISO9001 and ISO14001 | |

| Dimension bore tolerances | -/+0.01mm | |

| Quality standard | AGMA, JIS, DIN | |

| Surface treatment | Blackening, plated, anodizing, hard anodizing etc | |

| Gear hardness | 30 to 60 H.R.C | |

| Size/Color | Gears and parts dimensions are according to drawings from customer, and colors are customized | |

| Surface treatment | Polished or matte surface, painting, texture, vacuum aluminizing and can be stamped with logo etc. | |

| Dimensions Tolerance | ±0.01mm or more precise | |

| Samples confirmation and approval | samples shipped for confirmation and shipping cost paid by customers | |

| Package | Inner clear plastic bag/outside carton/wooden pallets/ or any other special package as per customer’s requirements. | |

| Delivery Time | Total takes 2~~8weeks usually | |

| Shipping |

Usual FEDEX, UPS, DHL, TNT, EMS or base on customer’s requirement. |

Production management:

1. The workers are trained to inspect the gears and notice any defect in production in time.

2. QC will check 1pcs every 100pcs in CNC machining, and gears will meet all dimension tolerances.

3. Gears will be inspected at every step, and gears will be inspected before shipment, and all inspection records will be kept in our factory for 3 years.

4. Our sales will send you pictures at every gears production steps, and you will know the detailed production status, and you can notice any possibility of mistake, for our sales, QC and workers are keeping close watch on all production.

5. You will feel us working very carefully to assure the quality and easy to work with,

6. we cherish every inquiry, every opportunity to make gears and parts and cherish every customer.

QUALITY CONTROL PROCESS:

1) Inspecting the raw material –IQC)

2) Checking the details before the production line operated

3) Have full inspection and routing inspection during mass production—In process quality control (IPQC)

4) Checking the gears after production finished—- (FQC)

5) Checking the gears after they are finished—–Outgoing quality control (OQC)

Service:

1. Molds designs as per customers’ gears drawing;

2. Submitting molds drawings to customers to review and confirm before mols production.

3. Providing samples with whole dimensions and cosmetic inspection report, material certification to customers.

4. Providing inspection report of important dimensions and cosmetic in batches parts.

Packing and shipment:

1. Gears are well and carefully packed in PP bags in CTNS, strong enough for express shipping, air shipment or sea shipment.

2. Air shipment, sea shipment or shipment by DHL, UPS, FedEx or TNT are availabe.

3. Trade terms: EXW, FOB HangZhou, or CIF

4. All shippings will be carefully arranged and will reach your places fast and safely.

FAQ

Q1: How to guarantee the Quality of gears and parts?

We are ISO 9001:2008 certified factory and we have the integrated system for industrial parts quality control. We have IQC (incoming quality control),

IPQCS (in process quality control section), FQC (final quality control) and OQC (out-going quality control) to control each process of industrial parts prodution.

Q2: What are the Advantage of your gears and parts?

Our advantage is the competitive and reasonable prices, fast delivery and high quality. Our eployees are responsible-oriented, friendly-oriented,and dilient-oriented.

Our industrial parts products are featured by strict tolerance, smooth finish and long-life performance.

Q3: what are our machining equipments?

Our machining equipments include plasticn injection machinies, CNC milling machines, CNC turning machines, stamping machines, hobbing machines, automatic lathe machines, tapping machines, grinding machines, cutting machines and so on.

Q4: What shipping ways do you use?

Generally, we will use UPS DHL or FEDEX and sea shipping

5: What materials can you process?

For plastic injection gears and parts, the materials are Nylon, PA66, NYLON with 30% glass fibre, ABS, PP,PC,PE,POM,PVC,PU,TPR,TPE,TPU,PA,PET,HDPE,PMMA etc.

For metal and machining gears and parts, the materials are brass, bronze, copper, stainless steel, steel, aluminum, titanium plastic etc.

Q6: How long is the Delivery for Your gears and parts?

Generally , it will take us 15 working days for injection or machining, and we will try to shorten our lead time.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Electric Cars, Machinery, Toy, Agricultural Machinery, Car |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Gear Position: | External Gear |

| Manufacturing Method: | Cut Gear |

| Toothed Portion Shape: | Curved Gear |

| Material: | Stainless Steel |

| Samples: |

US$ 10/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

How does the choice of materials impact the performance of plastic wheels in different settings?

The choice of materials significantly impacts the performance of plastic wheels in various settings. Different plastics offer unique properties that make them suitable for specific applications and environments. Here’s how material choice affects plastic wheel performance:

- 1. Durability: High-quality plastics like polyurethane and nylon are known for their durability. They resist wear and tear, making them ideal for heavy-duty settings, such as industrial equipment or manufacturing environments.

- 2. Load Capacity: The material’s strength and rigidity influence a plastic wheel’s load-bearing capacity. Reinforced plastics or materials like glass-filled nylon can handle heavier loads compared to softer plastics like polypropylene.

- 3. Chemical Resistance: Certain plastic materials, such as polypropylene, offer excellent chemical resistance. They are suitable for applications where exposure to chemicals or acids is a concern, like laboratories or chemical processing plants.

- 4. Temperature Tolerance: Some plastics are designed to withstand extreme temperatures. For example, acetal (POM) wheels can handle both high and low-temperature environments, making them suitable for freezer or high-heat applications.

- 5. Moisture Resistance: Plastics like polyurethane and nylon are moisture-resistant and do not absorb water. This property ensures that the wheels remain functional even in wet conditions, such as outdoor use or in humid environments.

- 6. UV Resistance: UV-resistant plastics can endure prolonged exposure to sunlight without becoming brittle or degrading. This feature is essential for outdoor applications like lawnmowers or garden equipment.

- 7. Non-Marking: Soft, non-marking plastics are used in applications where floor protection is crucial. These wheels prevent scuffing or damage to delicate flooring surfaces.

- 8. Weight: The choice of material impacts the weight of the wheel. Lighter plastics are preferred for applications where weight reduction is essential, such as aircraft ground support equipment.

- 9. Noise Level: Some plastic materials are designed to reduce noise when in operation. They offer quieter movement, making them suitable for environments where noise reduction is a priority.

- 10. Cost: Material choice can affect the cost of plastic wheels. High-performance plastics often come at a higher price point, while standard plastics like polypropylene are more cost-effective.

The selection of the right plastic material depends on the specific demands of the setting and application. Engineers and manufacturers choose materials that align with the environmental conditions, load requirements, and performance expectations to ensure that plastic wheels deliver optimal results.

Can you provide insights into the importance of proper installation and alignment of plastic wheels?

The proper installation and alignment of plastic wheels are crucial for ensuring optimal performance, safety, and longevity in various applications. Here are key insights into their importance:

- 1. Load Distribution: Correct installation ensures that the weight load is evenly distributed across all wheels. Proper weight distribution prevents overloading of individual wheels, reducing the risk of premature wear and potential wheel failure.

- 2. Reduced Friction: Properly aligned wheels minimize friction and rolling resistance. Misalignment can result in increased friction, requiring more effort to move equipment or objects. This can lead to reduced efficiency and increased wear on the wheels.

- 3. Improved Maneuverability: Properly aligned wheels provide better maneuverability and control. Whether in industrial settings or everyday use, aligned wheels allow for smooth and precise movement, enhancing productivity and safety.

- 4. Floor Protection: Aligning wheels correctly helps protect flooring surfaces. Misaligned or unevenly loaded wheels can cause floor damage, such as scuffs, scratches, or dents, which can be costly to repair.

- 5. Enhanced Stability: Proper alignment contributes to the stability of equipment and vehicles. Misaligned wheels can result in wobbling or instability, posing safety hazards and potentially causing accidents or damage.

- 6. Longevity: Proper installation and alignment extend the service life of plastic wheels. Misalignment can lead to uneven wear, reducing the lifespan of the wheels and necessitating premature replacements.

- 7. Noise Reduction: Misaligned wheels can generate noise due to uneven rolling. Proper alignment minimizes noise pollution, making plastic wheels suitable for applications where quiet operation is essential.

- 8. Safety: Ensuring that wheels are correctly installed and aligned is crucial for safety. Misalignment or improper installation can lead to accidents, equipment failure, and injuries, especially in industrial and automotive settings.

- 9. Maintenance Efficiency: Properly aligned wheels are easier to maintain. Routine inspections and maintenance tasks are more straightforward when wheels are aligned, reducing downtime and maintenance costs.

- 10. Performance Consistency: Correct alignment results in consistent performance. This is essential for applications where precision and repeatability are critical, such as conveyor systems or automated machinery.

In summary, proper installation and alignment of plastic wheels are fundamental to their functionality and performance. They contribute to load distribution, reduced friction, improved maneuverability, floor protection, stability, longevity, noise reduction, safety, maintenance efficiency, and performance consistency. Neglecting alignment can lead to various issues that impact efficiency, safety, and the overall quality of operations.

Can you explain the primary functions and applications of plastic wheels in various industries?

Plastic wheels serve essential functions in various industries due to their unique properties and versatility. Here are the primary functions and applications of plastic wheels in different industries:

- 1. Material Handling: Plastic wheels are widely used in material handling equipment, including carts, dollies, and conveyor systems. They provide smooth and noiseless movement, making them suitable for transporting goods in warehouses, factories, and distribution centers.

- 2. Office Furniture: Plastic wheels are commonly found on office chairs and furniture. They allow for easy mobility, quiet operation, and floor protection. These wheels are often made from soft materials like polyurethane to prevent damage to flooring.

- 3. Automotive: In the automotive industry, plastic wheels are used for various applications, including caster wheels on tool carts, wheels for automotive jacks, and even lightweight spare tire wheels. They offer a balance of durability, weight savings, and cost-effectiveness.

- 4. Retail and Shopping Carts: Plastic wheels are a staple in retail and shopping cart applications. They provide smooth and silent movement for shoppers while navigating stores. The lightweight nature of plastic wheels reduces cart weight, making them easier to push.

- 5. Medical Equipment: Plastic wheels are used in medical equipment, such as hospital carts and medical devices. Their non-corrosive properties, lightweight design, and ease of cleaning make them suitable for healthcare settings.

- 6. Aerospace: In the aerospace industry, plastic wheels are used in ground support equipment, maintenance carts, and aircraft cabin service carts. Their lightweight construction is advantageous for handling equipment around aircraft.

- 7. Food and Beverage: Plastic wheels are found in food service equipment, including food carts, serving trolleys, and food processing machinery. They are resistant to moisture and corrosion, which is critical in food handling environments.

- 8. Recreational Vehicles (RVs) and Trailers: Plastic wheels are used in RV leveling jacks and trailer jacks. They provide stability and easy adjustment for leveling RVs and trailers when parked.

- 9. DIY and Home Improvement: Plastic wheels are used in DIY projects and home improvement applications. They can be found on hand trucks, utility carts, and DIY furniture, offering ease of movement and floor protection.

- 10. Marine and Boating: Plastic wheels are used on boat trailers and marine equipment. They resist corrosion from saltwater exposure and offer buoyancy, making them ideal for marine applications.

- 11. Agriculture: In agriculture, plastic wheels are used on farm equipment, including wheelbarrows and agricultural carts. They provide durability and easy maneuverability in outdoor and rugged environments.

Plastic wheels are valued for their lightweight, corrosion resistance, cost-effectiveness, and adaptability across a wide range of industries. They play a vital role in improving mobility, efficiency, and performance in various applications.

editor by Dream 2024-05-08

China best S57 Series Helical Worm Geared Motor with Good quality

Solution Description

S collection Helical Geared Motor Traits

1. Features:

- Substantial performance: seventy five%-80%

- Substantial technological innovation: the helical equipment and a worm equipment merged with an integrated transmission to improve the torque and performance.

- High precision: the equipment is made of large-quality alloy metal forging, carbonitriding and hardening treatment method, grinding approach to make sure large precision and steady running.

- Large interchangeability: hugely modular, serial style, powerful versatility and interchangeability.

two. Specialized parameters

About Us

ZheJiang CZPT Co.,Ltd,the predecessor was a point out-owned armed forces CZPT business, was recognized in 1965. CZPT specializes in the full electricity transmission solution for substantial-conclude equipment manufacturing industries based mostly on the purpose of “System Solution, Software Design and style and Expert Service”.

Starshine have a robust technological pressure with in excess of 350 employees at existing, like over 30 engineering professionals, 30 good quality inspectors, masking an location of 80000 sq. meters and varieties of advanced processing equipment and screening equipments. We have a very good foundation for the business software advancement and services of large-stop velocity reducers & variators proudly owning to the provincial engineering technologies analysis middle,the lab of gear pace reducers, and the foundation of CZPT R&D.

Our Group

High quality Manage

High quality:Insist on Improvement,Strive for Excellence With the development of equipment manufacturing indurstry,customer never satirsfy with the current quality of our products,on the contrary,wcreate the value of quality.

Quality policy:to enhance the overall level in the field of power transmission

Quality View:Continuous Improvement , pursuit of excellence

Quality Philosophy:Quality creates value

three. Incoming Quality Control

To establish the AQL acceptable level of incoming material control, to provide the material for the whole inspection, sampling, immunity. On the acceptance of qualified products to warehousing, substandard goods to take return, check, rework, rework inspection responsible for tracking bad, to monitor the supplier to take corrective

measures to prevent recurrence.

four. Process Quality Control

The manufacturing site of the first examination, inspection and final inspection, sampling according to the requirements of some projects, judging the quality change trend

found abnormal phenomenon of manufacturing, and supervise the production department to improve, eliminate the abnormal phenomenon or state.

5. FQC(Final QC)

After the manufacturing department will complete the product, stand in the customer’s position on the finished product quality verification, in order to ensure the quality of

customer expectations and needs.

six. OQC(Outgoing QC)

After the product sample inspection to determine the qualified, allowing storage, but when the finished product from the warehouse before the formal delivery of the goods, there is a check, this is called the shipment inspection.Check content:In the warehouse storage and transfer status to confirm, while confirming the delivery of the

merchandise is a product inspection to determine the qualified products.

7. Certification.

Packing

Supply

What Are Worm Gears and Worm Shafts?

If you happen to be seeking for a fishing reel with a worm gear program, you’ve got almost certainly arrive throughout the phrase ‘worm gear’. But what are worm gears and worm shafts? And what are the benefits and negatives of worm gears? Let’s consider a nearer search! Study on to learn far more about worm gears and shafts! Then you will be nicely on your way to buying a reel with a worm equipment program.

worm gear reducers

Worm shaft reducers have a variety of benefits more than typical equipment reduction mechanisms. Very first, they are hugely productive. While solitary stage worm reducers have a greatest reduction ratio of about 5 to sixty, hypoid gears can typically go up to a greatest of 1 hundred and 20 moments. A worm shaft reducer is only as productive as the gearing it makes use of. This write-up will examine some of the positive aspects of utilizing a hypoid equipment set, and how it can gain your organization.

To assemble a worm shaft reducer, very first take away the flange from the motor. Then, get rid of the output bearing carrier and output equipment assembly. And lastly, set up the intermediate worm assembly via the bore opposite to the attachment housing. When set up, you should very carefully remove the bearing provider and the equipment assembly from the motor. Will not fail to remember to get rid of the oil seal from the housing and motor flange. During this procedure, you have to use a modest hammer to tap around the confront of the plug in close proximity to the outside diameter of the housing.

Worm gears are frequently used in reversing prevention systems. The backlash of a worm gear can boost with dress in. Even so, a duplex worm equipment was created to address this problem. This kind of gear needs a more compact backlash but is still very exact. It utilizes different prospects for the opposing tooth experience, which constantly alters its tooth thickness. Worm gears can also be adjusted axially.

worm gears

There are a couple of different kinds of lubricants that are utilised in worm gears. The first, polyalkylene glycols, are utilized in instances the place high temperature is not a concern. This type of lubricant does not contain any waxes, which can make it an exceptional option in minimal-temperature apps. Nonetheless, these lubricants are not compatible with mineral oils or some sorts of paints and seals. Worm gears generally feature a metal worm and a brass wheel. The brass wheel is much simpler to remodel than metal and is usually modeled as a sacrificial part.

The worm gear is most efficient when it is employed in modest and compact programs. Worm gears can drastically improve torque or reduce pace, and they are frequently used the place place is an issue. Worm gears are among the smoothest and quietest equipment systems on the market, and their meshing performance is superb. Nonetheless, the worm equipment demands higher-top quality manufacturing to perform at its maximum levels. If you might be considering a worm gear for a project, it truly is essential to make positive that you find a maker with a long and high top quality reputation.

The pitch diameters of the two worm and pinion gears must match. The two worm cylinders in a worm wheel have the very same pitch diameter. The worm wheel shaft has two pitch cylinders and two threads. They are related in pitch diameter, but have diverse advancing angles. A self-locking worm equipment, also identified as a wormwheel, is generally self-locking. Additionally, self-locking worm gears are easy to set up.

worm shafts

The deflection of worm shafts differs with toothing parameters. In addition to toothing duration, worm equipment measurement and strain angle, worm gear dimensions and number of helical threads are all influencing aspects. These versions are modeled in the standard ISO/TS 14521 reference equipment. This table shows the variants in every single parameter. The ID indicates the worm shaft’s centre length. In addition, a new calculation method is offered for determining the equal bending diameter of the worm.

The deflection of worm shafts is investigated employing a 4-phase process. 1st, the finite element strategy is used to compute the deflection of a worm shaft. Then, the worm shaft is experimentally analyzed, evaluating the outcomes with the corresponding simulations. The closing stage of the simulation is to contemplate the toothing geometry of fifteen diverse worm gear toothings. The benefits of this phase validate the modeled outcomes.

The direct on the correct and remaining tooth surfaces of worms is the same. Even so, the direct can be assorted together the worm shaft. This is referred to as twin guide worm gear, and is employed to eliminate engage in in the primary worm gear of hobbing equipment. The pitch diameters of worm modules are equivalent. The very same theory applies to their pitch diameters. Usually, the direct angle will increase as the number of threads decreases. That’s why, the larger the guide angle, the significantly less self-locking it gets.

worm gears in fishing reels

Fishing reels normally include worm shafts as a component of the construction. Worm shafts in fishing reels let for uniform worm winding. The worm shaft is attached to a bearing on the rear wall of the reel unit via a gap. The worm shaft’s entrance end is supported by a concave hole in the entrance of the reel unit. A traditional fishing reel may possibly also have a worm shaft hooked up to the sidewall.

The gear assistance portion 29 supports the rear finish of the pinion equipment 12. It is a thick rib that protrudes from the lid part 2 b. It is mounted on a bushing 14 b, which has a by way of gap via which the worm shaft 20 passes. This worm equipment supports the worm. There are two kinds of worm gears offered for fishing reels. The two kinds of worm gears might have distinct number of tooth or they might be the very same.

Normal worm shafts are made of stainless metal. Stainless metal worm shafts are specifically corrosion-resistant and resilient. Worm shafts are used on spinning reels, spin-casting reels, and in numerous electrical resources. A worm shaft can be reversible, but it is not completely reputable. There are many rewards of worm shafts in fishing reels. These fishing reels also feature a line winder or degree winder.

worm gears in electrical instruments

Worms have distinct tooth designs that can assist improve the load carrying capability of a worm gear. Various tooth designs can be utilised with circular or secondary curve cross sections. The pitch point of the cross segment is the boundary for this type of mesh. The mesh can be possibly positive or adverse relying on the desired torque. Worm enamel can also be inspected by measuring them more than pins. In several circumstances, the lead thickness of a worm can be altered using a gear tooth caliper.

The worm shaft is fixed to the lower case section 8 via a rubber bush 13. The worm wheel 3 is connected to the joint shaft 12. The worm 2 is coaxially connected to the shaft stop section 12a. This joint shaft connects to a swing arm and rotates the worm wheel 3.

The backlash of a worm equipment may possibly be improved if the worm is not mounted correctly. To resolve the issue, manufacturers have produced duplex worm gears, which are suited for small backlash apps. Duplex worm gears utilize distinct prospects on each and every tooth experience for ongoing change in tooth thickness. In this way, the heart distance of the worm equipment can be adjusted without changing the worm’s style.

worm gears in engines

Using worm shafts in engines has a couple of benefits. Very first of all, worm gears are peaceful. The equipment and worm experience go in reverse directions so the power transferred is linear. Worm gears are well-known in programs in which torque is crucial, such as elevators and lifts. Worm gears also have the benefit of being created from comfortable materials, making them simple to lubricate and to use in applications in which noise is a worry.

Lubricants are necessary for worm gears. The viscosity of lubricants determines whether the worm is in a position to touch the equipment or wheel. Typical lubricants are ISO 680 and 460, but larger viscosity oil is not uncommon. It is vital to use the proper lubricants for worm gears, given that they cannot be lubricated indefinitely.

Worm gears are not suggested for engines thanks to their limited functionality. The worm gear’s spiral movement leads to a important reduction in room, but this needs a substantial volume of lubrication. Worm gears are susceptible to breaking down since of the pressure placed on them. Moreover, their restricted pace can trigger substantial hurt to the gearbox, so watchful routine maintenance is important. To make confident worm gears remain in prime condition, you must inspect and clear them often.

Approaches for manufacturing worm shafts

A novel strategy to production worm shafts and gearboxes is offered by the approaches of the present creation. Factors of the technique entail manufacturing the worm shaft from a typical worm shaft blank obtaining a described outer diameter and axial pitch. The worm shaft blank is then adapted to the sought after gear ratio, resulting in a gearbox household with numerous equipment ratios. The chosen method for manufacturing worm shafts and gearboxes is outlined beneath.

A worm shaft assembly procedure may possibly entail developing an axial pitch for a offered frame measurement and reduction ratio. A single worm shaft blank normally has an outer diameter of 100 millimeters, which is the measurement of the worm equipment set’s centre distance. Upon completion of the assembly procedure, the worm shaft has the sought after axial pitch. Methods for manufacturing worm shafts contain the subsequent:

For the design of the worm gear, a high degree of conformity is necessary. Worm gears are categorised as a screw pair in the reduce pairs. Worm gears have high relative sliding, which is advantageous when comparing them to other sorts of gears. Worm gears need great surface finish and rigid positioning. Worm equipment lubrication generally includes floor active additives this kind of as silica or phosphor-bronze. Worm gear lubricants are usually blended. The lubricant movie that types on the equipment tooth has small impact on put on and is usually a excellent lubricant.

China Good quality Right-Angle Shaft Worm Helical Worm Gearbox S Series Reducer with Best Sales

Merchandise Description

S sequence Helical Geared Motor Qualities

one. Functions:

- High performance: 75%-80%

- High technology: the helical gear and a worm equipment merged with an built-in transmission to increase the torque and performance.

- High precision: the gear is made of large-good quality alloy steel forging, carbonitriding and hardening therapy, grinding procedure to ensure high precision and secure managing.

- Higher interchangeability: extremely modular, serial design and style, powerful flexibility and interchangeability.

2. Technological parameters

About Us

ZheJiang CZPT Co.,Ltd,the predecessor was a condition-owned military CZPT business, was set up in 1965. CZPT specializes in the comprehensive energy transmission resolution for large-conclude gear producing industries dependent on the purpose of “Platform Item, Software Design and Professional Provider”.

Starshine have a powerful complex power with in excess of 350 employees at current, including over 30 engineering experts, 30 high quality inspectors, covering an spot of 80000 sq. meters and kinds of innovative processing equipment and screening equipments. We have a very good basis for the market application advancement and support of substantial-stop velocity reducers & variators proudly owning to the provincial engineering technologies research heart,the lab of equipment pace reducers, and the foundation of CZPT R&D.

Our Team

Good quality Handle

Quality:Insist on Improvement,Strive for Excellence With the development of equipment manufacturing indurstry,customer never satirsfy with the current quality of our products,on the contrary,wcreate the value of quality.

Quality policy:to enhance the overall level in the field of power transmission

Quality View:Continuous Improvement , pursuit of excellence

Quality Philosophy:Quality creates value

3. Incoming Quality Control

To establish the AQL acceptable level of incoming material control, to provide the material for the whole inspection, sampling, immunity. On the acceptance of qualified products to warehousing, substandard goods to take return, check, rework, rework inspection responsible for tracking bad, to monitor the supplier to take corrective

measures to prevent recurrence.

4. Process Quality Control

The manufacturing site of the first examination, inspection and final inspection, sampling according to the requirements of some projects, judging the quality change trend

found abnormal phenomenon of manufacturing, and supervise the production department to improve, eliminate the abnormal phenomenon or state.

five. FQC(Final QC)

After the manufacturing department will complete the product, stand in the customer’s position on the finished product quality verification, in order to ensure the quality of

customer expectations and needs.

six. OQC(Outgoing QC)

After the product sample inspection to determine the qualified, allowing storage, but when the finished product from the warehouse before the formal delivery of the goods, there is a check, this is called the shipment inspection.Check content:In the warehouse storage and transfer status to confirm, while confirming the delivery of the

solution is a product inspection to determine the qualified products.

seven. Certification.

Packing

Delivery

What Are Worm Gears and Worm Shafts?

If you are hunting for a fishing reel with a worm gear method, you’ve almost certainly come across the expression ‘worm gear’. But what are worm gears and worm shafts? And what are the advantages and drawbacks of worm gears? Let’s take a nearer seem! Study on to discover more about worm gears and shafts! Then you will be effectively on your way to buying a reel with a worm gear program.

worm equipment reducers

Worm shaft reducers have a variety of benefits over conventional gear reduction mechanisms. First, they’re hugely efficient. While one phase worm reducers have a highest reduction ratio of about 5 to sixty, hypoid gears can typically go up to a greatest of one particular hundred and twenty occasions. A worm shaft reducer is only as productive as the gearing it makes use of. This report will go over some of the advantages of employing a hypoid gear set, and how it can benefit your organization.

To assemble a worm shaft reducer, initial take away the flange from the motor. Then, remove the output bearing carrier and output gear assembly. Lastly, set up the intermediate worm assembly via the bore opposite to the attachment housing. After installed, you ought to meticulously get rid of the bearing provider and the equipment assembly from the motor. Don’t neglect to get rid of the oil seal from the housing and motor flange. During this process, you should use a tiny hammer to faucet about the encounter of the plug close to the outdoors diameter of the housing.

Worm gears are usually employed in reversing avoidance systems. The backlash of a worm equipment can increase with dress in. However, a duplex worm equipment was created to tackle this difficulty. This type of gear requires a smaller backlash but is even now hugely exact. It uses different leads for the opposing tooth experience, which constantly alters its tooth thickness. Worm gears can also be altered axially.

worm gears

There are a pair of different kinds of lubricants that are utilized in worm gears. The initial, polyalkylene glycols, are utilized in instances in which substantial temperature is not a issue. This type of lubricant does not incorporate any waxes, which can make it an excellent choice in low-temperature programs. Nevertheless, these lubricants are not appropriate with mineral oils or some types of paints and seals. Worm gears normally function a metal worm and a brass wheel. The brass wheel is much less complicated to transform than metal and is normally modeled as a sacrificial component.

The worm equipment is most successful when it is utilized in little and compact applications. Worm gears can drastically boost torque or minimize velocity, and they are usually utilised the place room is an issue. Worm gears are between the smoothest and quietest equipment systems on the market, and their meshing efficiency is excellent. However, the worm gear requires high-quality production to perform at its optimum levels. If you are considering a worm equipment for a task, it truly is important to make sure that you discover a company with a lengthy and substantial high quality reputation.

The pitch diameters of both worm and pinion gears should match. The two worm cylinders in a worm wheel have the identical pitch diameter. The worm wheel shaft has two pitch cylinders and two threads. They are equivalent in pitch diameter, but have various advancing angles. A self-locking worm gear, also recognized as a wormwheel, is usually self-locking. Additionally, self-locking worm gears are simple to set up.

worm shafts

The deflection of worm shafts differs with toothing parameters. In addition to toothing length, worm equipment size and stress angle, worm gear measurement and quantity of helical threads are all influencing elements. These variations are modeled in the common ISO/TS 14521 reference equipment. This table shows the variants in each and every parameter. The ID suggests the worm shaft’s heart length. In addition, a new calculation approach is presented for deciding the equal bending diameter of the worm.

The deflection of worm shafts is investigated using a 4-stage process. 1st, the finite aspect technique is utilised to compute the deflection of a worm shaft. Then, the worm shaft is experimentally tested, evaluating the outcomes with the corresponding simulations. The last stage of the simulation is to contemplate the toothing geometry of fifteen different worm equipment toothings. The benefits of this stage confirm the modeled outcomes.

The direct on the correct and remaining tooth surfaces of worms is the very same. Nevertheless, the guide can be varied together the worm shaft. This is named twin direct worm equipment, and is utilised to get rid of play in the major worm gear of hobbing machines. The pitch diameters of worm modules are equal. The very same basic principle applies to their pitch diameters. Generally, the guide angle raises as the quantity of threads decreases. Therefore, the bigger the direct angle, the much less self-locking it turns into.

worm gears in fishing reels

Fishing reels normally consist of worm shafts as a portion of the building. Worm shafts in fishing reels let for uniform worm winding. The worm shaft is hooked up to a bearing on the rear wall of the reel unit by way of a gap. The worm shaft’s front stop is supported by a concave gap in the entrance of the reel device. A traditional fishing reel may also have a worm shaft hooked up to the sidewall.

The gear assist part 29 supports the rear conclude of the pinion gear twelve. It is a thick rib that protrudes from the lid part 2 b. It is mounted on a bushing 14 b, which has a via gap by way of which the worm shaft 20 passes. This worm gear supports the worm. There are two kinds of worm gears available for fishing reels. The two kinds of worm gears may possibly have distinct variety of enamel or they may possibly be the identical.

Normal worm shafts are created of stainless metal. Stainless metal worm shafts are specially corrosion-resistant and tough. Worm shafts are employed on spinning reels, spin-casting reels, and in several electrical equipment. A worm shaft can be reversible, but it is not completely dependable. There are many rewards of worm shafts in fishing reels. These fishing reels also attribute a line winder or level winder.

worm gears in electrical resources

Worms have diverse tooth shapes that can assist improve the load carrying capacity of a worm gear. Diverse tooth designs can be utilized with round or secondary curve cross sections. The pitch position of the cross part is the boundary for this sort of mesh. The mesh can be both positive or adverse based on the desired torque. Worm teeth can also be inspected by measuring them over pins. In a lot of cases, the guide thickness of a worm can be modified making use of a equipment tooth caliper.

The worm shaft is fixed to the reduced situation segment 8 via a rubber bush 13. The worm wheel 3 is attached to the joint shaft 12. The worm 2 is coaxially hooked up to the shaft end section 12a. This joint shaft connects to a swing arm and rotates the worm wheel 3.

The backlash of a worm gear might be elevated if the worm is not mounted properly. To resolve the issue, companies have designed duplex worm gears, which are suited for modest backlash programs. Duplex worm gears make use of various leads on every single tooth confront for steady change in tooth thickness. In this way, the centre distance of the worm equipment can be adjusted with no modifying the worm’s design and style.

worm gears in engines

Using worm shafts in engines has a couple of advantages. Very first of all, worm gears are tranquil. The equipment and worm experience go in reverse directions so the vitality transferred is linear. Worm gears are well-liked in purposes the place torque is crucial, this kind of as elevators and lifts. Worm gears also have the benefit of becoming produced from delicate materials, making them straightforward to lubricate and to use in apps where sound is a problem.

Lubricants are essential for worm gears. The viscosity of lubricants decides regardless of whether the worm is capable to touch the equipment or wheel. Frequent lubricants are ISO 680 and 460, but increased viscosity oil is not unheard of. It is vital to use the proper lubricants for worm gears, since they can’t be lubricated indefinitely.

Worm gears are not advised for engines because of to their minimal efficiency. The worm gear’s spiral motion brings about a substantial reduction in place, but this calls for a substantial quantity of lubrication. Worm gears are vulnerable to breaking down due to the fact of the tension placed on them. In addition, their limited speed can trigger important injury to the gearbox, so watchful servicing is vital. To make certain worm gears stay in best problem, you must examine and clean them frequently.

Methods for manufacturing worm shafts

A novel method to production worm shafts and gearboxes is presented by the strategies of the existing creation. Facets of the strategy require manufacturing the worm shaft from a frequent worm shaft blank having a described outer diameter and axial pitch. The worm shaft blank is then tailored to the sought after equipment ratio, resulting in a gearbox household with multiple gear ratios. The favored method for manufacturing worm shafts and gearboxes is outlined beneath.

A worm shaft assembly approach may possibly include setting up an axial pitch for a presented body dimension and reduction ratio. A one worm shaft blank usually has an outer diameter of 100 millimeters, which is the measurement of the worm equipment set’s middle length. Upon completion of the assembly process, the worm shaft has the wanted axial pitch. Approaches for producing worm shafts contain the following:

For the style of the worm equipment, a substantial degree of conformity is essential. Worm gears are categorised as a screw pair in the decrease pairs. Worm gears have higher relative sliding, which is useful when evaluating them to other sorts of gears. Worm gears require excellent surface complete and rigid positioning. Worm gear lubrication normally comprises surface area lively additives these kinds of as silica or phosphor-bronze. Worm equipment lubricants are often combined. The lubricant movie that varieties on the equipment tooth has little impact on wear and is generally a great lubricant.

China best High Precision Worm Bevel Helical Oval Rack Nylon Set Mod 2 Small 3D Printed Toy Injection One Shaft DC Shaft Motor Cog Plastic Gear Manufacturer with Best Sales

Merchandise Description

substantial precision worm bevel helical oval rack nylon established mod 2 modest 3d printed toy injection 1 shaft dc shaft motor cog plastic gear producer

Calculating the Deflection of a Worm Shaft

In this write-up, we will go over how to calculate the deflection of a worm gear’s worm shaft. We are going to also examine the qualities of a worm gear, including its tooth forces. And we are going to protect the critical qualities of a worm gear. Read through on to learn more! Below are some factors to consider before acquiring a worm equipment. We hope you enjoy finding out! Right after looking through this post, you may be nicely-geared up to pick a worm equipment to match your demands.

Calculation of worm shaft deflection

The principal aim of the calculations is to figure out the deflection of a worm. Worms are utilised to switch gears and mechanical gadgets. This type of transmission uses a worm. The worm diameter and the amount of teeth are inputted into the calculation steadily. Then, a table with proper answers is demonstrated on the screen. After finishing the table, you can then transfer on to the principal calculation. You can change the energy parameters as nicely.

The optimum worm shaft deflection is calculated employing the finite component approach (FEM). The product has many parameters, like the measurement of the components and boundary conditions. The benefits from these simulations are in contrast to the corresponding analytical values to calculate the greatest deflection. The end result is a table that displays the highest worm shaft deflection. The tables can be downloaded underneath. You can also locate a lot more info about the diverse deflection formulas and their purposes.

The calculation method used by DIN EN 10084 is dependent on the hardened cemented worm of 16MnCr5. Then, you can use DIN EN 10084 (CuSn12Ni2-C-GZ) and DIN EN 1982 (CuAl10Fe5Ne5-C-GZ). Then, you can enter the worm face width, either manually or utilizing the automobile-propose choice.

Widespread approaches for the calculation of worm shaft deflection supply a great approximation of deflection but do not account for geometric modifications on the worm. Although Norgauer’s 2021 method addresses these problems, it fails to account for the helical winding of the worm enamel and overestimates the stiffening impact of gearing. A lot more refined techniques are necessary for the effective layout of slender worm shafts.

Worm gears have a minimal sound and vibration compared to other types of mechanical products. Nonetheless, worm gears are usually constrained by the quantity of wear that happens on the softer worm wheel. Worm shaft deflection is a significant influencing issue for sounds and dress in. The calculation strategy for worm equipment deflection is obtainable in ISO/TR 14521, DIN 3996, and AGMA 6022.

The worm gear can be designed with a exact transmission ratio. The calculation entails dividing the transmission ratio between much more stages in a gearbox. Power transmission input parameters impact the gearing properties, as well as the materials of the worm/equipment. To attain a greater performance, the worm/gear substance ought to match the circumstances that are to be seasoned. The worm equipment can be a self-locking transmission.

The worm gearbox includes many equipment factors. The primary contributors to the whole energy decline are the axial hundreds and bearing losses on the worm shaft. Consequently, different bearing configurations are studied. One sort contains finding/non-locating bearing arrangements. The other is tapered roller bearings. The worm gear drives are regarded as when locating versus non-finding bearings. The investigation of worm equipment drives is also an investigation of the X-arrangement and four-position make contact with bearings.

Influence of tooth forces on bending stiffness of a worm gear

The bending stiffness of a worm gear is dependent on tooth forces. Tooth forces improve as the electricity density raises, but this also sales opportunities to enhanced worm shaft deflection. The ensuing deflection can impact efficiency, dress in load capability, and NVH behavior. Steady enhancements in bronze resources, lubricants, and producing quality have enabled worm equipment companies to make increasingly higher electricity densities.

Standardized calculation techniques consider into account the supporting result of the toothing on the worm shaft. Even so, overhung worm gears are not included in the calculation. In addition, the toothing location is not taken into account until the shaft is made following to the worm gear. In the same way, the root diameter is handled as the equal bending diameter, but this ignores the supporting impact of the worm toothing.

A generalized formulation is supplied to estimate the STE contribution to vibratory excitation. The outcomes are applicable to any gear with a meshing sample. It is suggested that engineers take a look at distinct meshing approaches to get far more precise final results. One particular way to test tooth-meshing surfaces is to use a finite aspect pressure and mesh subprogram. This application will evaluate tooth-bending stresses below dynamic hundreds.

The effect of tooth-brushing and lubricant on bending stiffness can be accomplished by escalating the stress angle of the worm pair. This can decrease tooth bending stresses in the worm equipment. A further technique is to include a load-loaded tooth-contact examination (CCTA). This is also utilised to evaluate mismatched ZC1 worm drive. The benefits received with the method have been commonly used to numerous sorts of gearing.

In this research, we identified that the ring gear’s bending stiffness is highly influenced by the enamel. The chamfered root of the ring gear is greater than the slot width. As a result, the ring gear’s bending stiffness differs with its tooth width, which raises with the ring wall thickness. Additionally, a variation in the ring wall thickness of the worm equipment leads to a better deviation from the layout specification.

To realize the effect of the enamel on the bending stiffness of a worm equipment, it is crucial to know the root shape. Involute teeth are prone to bending tension and can crack beneath severe circumstances. A tooth-breakage examination can control this by figuring out the root form and the bending stiffness. The optimization of the root form straight on the ultimate equipment minimizes the bending tension in the involute teeth.

The influence of tooth forces on the bending stiffness of a worm gear was investigated utilizing the CZPT Spiral Bevel Gear Take a look at Facility. In this review, a number of enamel of a spiral bevel pinion were instrumented with pressure gages and analyzed at speeds ranging from static to 14400 RPM. The exams had been executed with energy ranges as high as 540 kW. The outcomes attained have been in contrast with the investigation of a a few-dimensional finite element design.

Characteristics of worm gears

Worm gears are exclusive types of gears. They feature a range of qualities and apps. This article will look at the attributes and positive aspects of worm gears. Then, we are going to examine the widespread purposes of worm gears. Let us get a look! Just before we dive in to worm gears, let us overview their capabilities. With any luck ,, you will see how versatile these gears are.

A worm gear can obtain substantial reduction ratios with little effort. By adding circumference to the wheel, the worm can significantly boost its torque and decrease its speed. Conventional gearsets demand numerous reductions to obtain the very same reduction ratio. Worm gears have fewer shifting components, so there are less locations for failure. Even so, they are unable to reverse the route of electricity. This is due to the fact the friction amongst the worm and wheel can make it impossible to transfer the worm backwards.

Worm gears are extensively used in elevators, hoists, and lifts. They are notably beneficial in programs where stopping velocity is critical. They can be incorporated with smaller sized brakes to make certain basic safety, but shouldn’t be relied on as a main braking technique. Typically, they are self-locking, so they are a very good decision for several programs. They also have numerous rewards, including elevated performance and protection.

Worm gears are created to obtain a distinct reduction ratio. They are generally arranged in between the enter and output shafts of a motor and a load. The two shafts are usually positioned at an angle that ensures correct alignment. Worm equipment gears have a center spacing of a frame dimension. The centre spacing of the equipment and worm shaft decides the axial pitch. For occasion, if the gearsets are set at a radial distance, a smaller sized outer diameter is essential.

Worm gears’ sliding contact lowers performance. But it also assures tranquil procedure. The sliding motion limits the performance of worm gears to thirty% to 50%. A handful of methods are launched herein to decrease friction and to make great entrance and exit gaps. You will soon see why they are such a versatile decision for your requirements! So, if you might be thinking about buying a worm equipment, make sure you read through this write-up to find out a lot more about its characteristics!

An embodiment of a worm equipment is described in FIGS. 19 and 20. An alternate embodiment of the technique uses a solitary motor and a single worm 153. The worm 153 turns a equipment which drives an arm 152. The arm 152, in change, moves the lens/mirr assembly ten by varying the elevation angle. The motor manage unit 114 then tracks the elevation angle of the lens/mirr assembly 10 in relation to the reference situation.

The worm wheel and worm are both produced of steel. Nevertheless, the brass worm and wheel are made of brass, which is a yellow steel. Their lubricant choices are far more versatile, but they’re constrained by additive restrictions due to their yellow metal. Plastic on metal worm gears are usually discovered in light-weight load programs. The lubricant employed is dependent on the kind of plastic, as a lot of kinds of plastics react to hydrocarbons located in regular lubricant. For this explanation, you want a non-reactive lubricant.

China best S Series Hollow Shaft Helical Worm Gear Box with Electric Motor near me supplier

Item Description

Solution Description

Product Attributes

High modular layout, biomimetic surface area with owned mental property appropriate.

Adopt German worm hob to process the worm wheel.

With the specific gear geometry, it gets high torque, performance and lengthy existence circle.

It can achieve the immediate combination for 2 sets of gearbox.

Mounting method: foot mounted, flange mounted, torque arm mounted.

Output shaft: reliable shaft, hollow shaft.

Primary used for

Chemical industry and environmental defense

Steel processing

Building and building

Agriculture and foodstuff

Textile and leather-based

Forest and paper

Car washing equipment

In depth Photos

Merchandise Parameters

Complex knowledge:

Our Positive aspects

Certifications

Packaging & Transport

Firm Profile

Xihu (West Lake) Dis.ng Transmission Gear Co., Ltd. situated HangZhou city, ZHangZhoug, as 1 professional producer and exporter of cycloidal pin wheel reducer,worm reducer, equipment reducer, gearbox , AC motor and relative spare elements, owns abundant experience in this line for a lot of several years.

We are 1 immediate manufacturing facility, with innovative creation tools, the robust development crew and producing capability to offer you quality items for customers.

Our merchandise commonly served to various industries of Metallurgy, Substances, lifting,mining,Petroleum,textile,medication,picket and so on. Major marketplaces: China, Africa,Australia,Vietnam, Turkey,Japan, Korea, Philippines…

Welcome to question us any questions, good offer you always for you for long time period business.

FAQ

Q: Are you buying and selling company or manufacturer?

A: We are manufacturing facility.

Q: How prolonged is your delivery time?

A: Generally it is 5-10 days if the products are in stock. or it is 15-20 times if the products are not in stock.

Q: Can we acquire 1 personal computer of each and every merchandise for top quality screening?

A: Of course, we are happy to settle for demo buy for good quality tests.

Q:How to pick a gearbox which satisfies your requirement?

A:You can refer to our catalogue to select the gearbox or we can aid to pick when you give

the complex info of essential output torque, output velocity and motor parameter and so forth.

Q: What info shall we give before placing a purchase purchase?

A:a) Sort of the gearbox, ratio, enter and output kind, enter flange, mounting position, and motor informationetc.

b) Housing coloration.

c) Acquire amount.

d) Other specific specifications.

An Overview of Worm Shafts and Gears

This write-up offers an overview of worm shafts and gears, such as the sort of toothing and deflection they experience. Other subject areas lined incorporate the use of aluminum vs . bronze worm shafts, calculating worm shaft deflection and lubrication. A extensive understanding of these problems will support you to design far better gearboxes and other worm gear mechanisms. For further info, make sure you check out the connected web sites. We also hope that you will find this article insightful.

Double throat worm gears

The pitch diameter of a worm and the pitch of its worm wheel should be equal. The two types of worm gears have the exact same pitch diameter, but the big difference lies in their axial and round pitches. The pitch diameter is the length amongst the worm’s teeth alongside its axis and the pitch diameter of the greater gear. Worms are created with remaining-handed or appropriate-handed threads. The lead of the worm is the length a point on the thread travels during 1 revolution of the worm gear. The backlash measurement must be made in a couple of various places on the equipment wheel, as a large quantity of backlash indicates tooth spacing.

A double-throat worm gear is developed for high-load apps. It offers the tightest connection amongst worm and equipment. It is crucial to mount a worm equipment assembly correctly. The keyway design and style calls for a number of factors of get in touch with, which block shaft rotation and help transfer torque to the gear. After identifying the location of the keyway, a gap is drilled into the hub, which is then screwed into the gear.

The twin-threaded layout of worm gears allows them to withstand heavy hundreds without slipping or tearing out of the worm. A double-throat worm gear supplies the tightest connection among worm and equipment, and is consequently ideal for hoisting programs. The self-locking mother nature of the worm equipment is another gain. If the worm gears are created well, they are superb for reducing speeds, as they are self-locking.

When selecting a worm, the number of threads that a worm has is vital. Thread starts figure out the reduction ratio of a pair, so the increased the threads, the higher the ratio. The very same is real for the worm helix angles, which can be one particular, two, or 3 threads prolonged. This varies amongst a one thread and a double-throat worm gear, and it is vital to take into account the helix angle when deciding on a worm.

Double-throat worm gears differ in their profile from the true gear. Double-throat worm gears are specifically helpful in purposes in which sound is an problem. In addition to their minimal noise, worm gears can absorb shock masses. A double-throat worm equipment is also a common selection for many various kinds of programs. These gears are also typically utilized for hoisting equipment. Its tooth profile is various from that of the actual gear.

Bronze or aluminum worm shafts

When deciding on a worm, a number of factors ought to be held in head. The materials of the shaft ought to be both bronze or aluminum. The worm itself is the main ingredient, but there are also addendum gears that are offered. The whole variety of teeth on both the worm and the addendum equipment should be better than forty. The axial pitch of the worm wants to match the round pitch of the bigger gear.

The most typical materials utilised for worm gears is bronze simply because of its attractive mechanical qualities. Bronze is a broad term referring to a variety of copper alloys, such as copper-nickel and copper-aluminum. Bronze is most generally designed by alloying copper with tin and aluminum. In some situations, this blend produces brass, which is a related metallic to bronze. The latter is much less pricey and suitable for light hundreds.

There are a lot of advantages to bronze worm gears. They are sturdy and resilient, and they provide exceptional put on-resistance. In contrast to steel worms, bronze worm gears are quieter than their counterparts. They also need no lubrication and are corrosion-resistant. Bronze worms are well-known with small, light-excess weight devices, as they are easy to maintain. You can read through more about worm gears in CZPT’s CZPT.

Though bronze or aluminum worm shafts are the most typical, equally components are equally appropriate for a assortment of applications. A bronze shaft is typically known as bronze but might really be brass. Historically, worm gears have been manufactured of SAE sixty five equipment bronze. Nonetheless, newer components have been released. SAE sixty five equipment bronze (UNS C90700) remains the preferred substance. For substantial-quantity purposes, the materials cost savings can be substantial.

Both varieties of worms are in essence the identical in size and form, but the direct on the left and correct tooth surfaces can fluctuate. This enables for specific adjustment of the backlash on a worm without having changing the middle distance among the worm equipment. The distinct measurements of worms also make them less complicated to manufacture and keep. But if you want an specifically small worm for an industrial application, you should think about bronze or aluminum.

Calculation of worm shaft deflection

The centre-line length of a worm equipment and the variety of worm tooth perform a essential position in the deflection of the rotor. These parameters need to be entered into the device in the exact same units as the major calculation. The selected variant is then transferred to the principal calculation. The deflection of the worm gear can be calculated from the angle at which the worm teeth shrink. The subsequent calculation is helpful for planning a worm equipment.

Worm gears are broadly used in industrial applications thanks to their high transmittable torques and massive equipment ratios. Their challenging/delicate materials combination helps make them preferably suited for a extensive range of programs. The worm shaft is typically manufactured of circumstance-hardened metal, and the worm wheel is fabricated from a copper-tin-bronze alloy. In most instances, the wheel is the spot of get in touch with with the gear. Worm gears also have a lower deflection, as large shaft deflection can affect the transmission precision and improve wear.

An additional approach for figuring out worm shaft deflection is to use the tooth-dependent bending stiffness of a worm gear’s toothing. By calculating the stiffness of the individual sections of a worm shaft, the stiffness of the entire worm can be identified. The approximate tooth area is shown in figure 5.

An additional way to determine worm shaft deflection is by employing the FEM technique. The simulation device makes use of an analytical model of the worm gear shaft to figure out the deflection of the worm. It is dependent on a two-dimensional product, which is a lot more suited for simulation. Then, you require to input the worm gear’s pitch angle and the toothing to calculate the maximum deflection.

Lubrication of worm shafts

In buy to protect the gears, worm drives require lubricants that offer you superb anti-dress in protection, large oxidation resistance, and lower friction. Although mineral oil lubricants are commonly utilized, synthetic foundation oils have far better performance traits and reduce running temperatures. The Arrhenius Rate Rule states that chemical reactions double every single ten degrees C. Artificial lubricants are the ideal choice for these applications.

Synthetics and compounded mineral oils are the most well-liked lubricants for worm gears. These oils are formulated with mineral basestock and four to six percent artificial fatty acid. Area-active additives give compounded equipment oils exceptional lubricity and avert sliding wear. These oils are suited for high-velocity applications, including worm gears. Nonetheless, synthetic oil has the drawback of becoming incompatible with polycarbonate and some paints.

Artificial lubricants are costly, but they can improve worm equipment performance and operating lifestyle. Synthetic lubricants usually drop into two classes: PAO artificial oils and EP artificial oils. The latter has a increased viscosity index and can be utilized at a assortment of temperatures. Synthetic lubricants typically have anti-put on additives and EP (anti-dress in).

Worm gears are frequently mounted above or below the gearbox. The appropriate lubrication is important to make sure the proper mounting and procedure. Frequently, insufficient lubrication can lead to the device to fall short faster than envisioned. Since of this, a technician could not make a relationship between the deficiency of lube and the failure of the device. It is important to stick to the manufacturer’s suggestions and use higher-top quality lubricant for your gearbox.

Worm drives decrease backlash by minimizing the perform among equipment teeth. Backlash can result in injury if unbalanced forces are introduced. Worm drives are lightweight and resilient simply because they have nominal transferring parts. In addition, worm drives are low-noise and vibration. In addition, their sliding motion scrapes absent extra lubricant. The consistent sliding action generates a large quantity of heat, which is why exceptional lubrication is vital.

Oils with a large movie power and superb adhesion are best for lubrication of worm gears. Some of these oils incorporate sulfur, which can etch a bronze equipment. In get to avoid this, it is critical to use a lubricant that has large film strength and prevents asperities from welding. The perfect lubricant for worm gears is one particular that gives excellent film strength and does not contain sulfur.

China Good quality High Efficiency Helical Worm Gear Reducer near me supplier

Solution Description

EWS sequence adopts helical gear – worm equipment pace reducer motor integrated push to increase the torque and performance of the pace reducer with vast range of CZPT speed and great universality, it is relevant to different installation modes and features safe and reputable performance, and long service existence, additionally, it also complies with the intercontinental standard.

Attribute advantage

one.Mixture of helical gear and worm, vertical output, compact construction, substantial speed ratio.

two.The concave-convex floor of the merchandise offers the operate of warmth dissipation, and features powerful vibration absorption, minimal temperature increase, low noise.

3.The merchandise characteristics substantial generate precision, and is specially appropriate for the internet site with regular begin, is can be connected with assorted pace reducers and configuring diverse motor drives, and can be set up at the 90º push operation website.

Specification parameter

Set up type : Foot,flange,tiny flange,torque arm.

Output variety : Solid shaft,hollow shaft,hollow shaft with shrink disk,spline hollow shaft.

Enter kind : Motor,enter shaft and flange

complex parameters : ratio i=23.8~389,mixture of EWS/EWR is up to26688

Efficiency : ratio i=23.8~389,seventy seven%ratio i=seventy three.7~389,62%and mix of EWS/EWR57%.

Industrial Application

Power Plant Equipment

Metallurgical Industry

Metal Forming Machinery

Petrochemical Industry

Mining Machine

Hoisting Machinery

Design Industry

Environmental Protection Industry

Cable Industry

Foods Machinery

Certificates

Handed ” ISO 9001 Worldwide Good quality Program Certificate”,”Europe CE Certificate”, ” Swiss SGS Certification”,”Higher-tech organization certification of ZheJiang metropolis”,”Excellent functionality management enterprise of ZheJiang city”,and so forth.

FAQ

1. Q: Can you make as for every custom made drawing?

A: Indeed, we offer tailored services for consumers.

two. Q: Are you a factory or investing business?

A. We are manufacturer in ZheJiang China.

3. Q: What is actually your MOQ?

A: One particular piece.

four. Q: What is actually your creation time?

A: 7-fifteen operating days following acquiring payment.

five. Q: What is your payment phrases?

A: T/T, 30% payment in advance, 70% equilibrium payment ought to be paid prior to shipping and delivery.

six. Q: What’s your bundle?

A: In wood box packaging.

ZheJiang EASTWELL Gear Reducer Co.,Ltd., previous a joint enterprise invested by is a ZheJiang EAST PUMP Group and Properly Organization of America.We are professional producer of the gear reducers and specialize in the gear reducers location in China for twenty years. EASTWELL has excellent R&D group,leading-rating generation and take a look at tools.So we have the sturdy electricity in the developing and producing the standards kind as properly as the tailored kind equipment reducer for our consumers.

Worm Equipment Motors

Worm gear motors are frequently desired for quieter procedure due to the fact of the clean sliding movement of the worm shaft. In contrast to gear motors with enamel, which might click on as the worm turns, worm gear motors can be set up in a silent spot. In this report, we will discuss about the CZPT whirling approach and the different types of worms obtainable. We will also go over the benefits of worm gear motors and worm wheel.

worm equipment

In the scenario of a worm gear, the axial pitch of the ring pinion of the corresponding revolving worm is equivalent to the round pitch of the mating revolving pinion of the worm equipment. A worm with one start off is recognized as a worm with a guide. This leads to a smaller sized worm wheel. Worms can work in limited areas because of their little profile.

Normally, a worm equipment has higher effectiveness, but there are a handful of negatives. Worm gears are not recommended for higher-heat purposes since of their higher amount of rubbing. A complete-fluid lubricant movie and the minimal put on stage of the gear reduce friction and use. Worm gears also have a decrease dress in charge than a regular gear. The worm shaft and worm equipment is also much more efficient than a regular gear.

The worm equipment shaft is cradled inside of a self-aligning bearing block that is connected to the gearbox casing. The eccentric housing has radial bearings on the two ends, enabling it to have interaction with the worm equipment wheel. The drive is transferred to the worm gear shaft by means of bevel gears 13A, a single fixed at the ends of the worm equipment shaft and the other in the center of the cross-shaft.

worm wheel

In a worm gearbox, the pinion or worm gear is centered amongst a geared cylinder and a worm shaft. The worm gear shaft is supported at either conclude by a radial thrust bearing. A gearbox’s cross-shaft is set to a suited drive signifies and pivotally connected to the worm wheel. The input drive is transferred to the worm equipment shaft ten via bevel gears 13A, one particular of which is fastened to the finish of the worm gear shaft and the other at the centre of the cross-shaft.

Worms and worm wheels are offered in numerous supplies. The worm wheel is produced of bronze alloy, aluminum, or steel. Aluminum bronze worm wheels are a good option for large-pace apps. Forged iron worm wheels are cheap and appropriate for mild loads. MC nylon worm wheels are extremely use-resistant and machinable. Aluminum bronze worm wheels are offered and are great for programs with serious use circumstances.

When creating a worm wheel, it is vital to figure out the right lubricant for the worm shaft and a corresponding worm wheel. A ideal lubricant need to have a kinematic viscosity of three hundred mm2/s and be utilized for worm wheel sleeve bearings. The worm wheel and worm shaft ought to be correctly lubricated to ensure their longevity.

Multi-commence worms

A multi-begin worm equipment screw jack brings together the benefits of multiple starts with linear output speeds. The multi-start off worm shaft lowers the outcomes of solitary start off worms and large ratio gears. Both varieties of worm gears have a reversible worm that can be reversed or stopped by hand, depending on the software. The worm gear’s self-locking capability depends on the lead angle, pressure angle, and friction coefficient.

A one-begin worm has a one thread managing the duration of its shaft. The worm advancements 1 tooth for each revolution. A multi-start worm has numerous threads in every single of its threads. The gear reduction on a multi-start worm is equivalent to the quantity of teeth on the equipment minus the quantity of commences on the worm shaft. In common, a multi-start worm has two or three threads.

Worm gears can be quieter than other types of gears since the worm shaft glides rather than clicking. This makes them an outstanding selection for purposes where sound is a problem. Worm gears can be made of softer materials, creating them far more sounds-tolerant. In addition, they can stand up to shock loads. In comparison to gears with toothed teeth, worm gears have a reduced sounds and vibration price.

CZPT whirling process

The CZPT whirling process for worm shafts raises the bar for precision gear machining in tiny to medium production volumes. The CZPT whirling process decreases thread rolling, raises worm high quality, and offers reduced cycle moments. The CZPT LWN-90 whirling machine attributes a steel bed, programmable force tailstock, and 5-axis interpolation for improved precision and good quality.

Its 4,000-rpm, 5-kW whirling spindle generates worms and different sorts of screws. Its outer diameters are up to 2.5 inches, while its duration is up to 20 inches. Its dry-chopping method uses a vortex tube to supply chilled compressed air to the chopping point. Oil is also additional to the combination. The worm shafts developed are free of undercuts, decreasing the volume of machining needed.

Induction hardening is a procedure that normally takes benefit of the whirling approach. The induction hardening procedure makes use of alternating existing (AC) to trigger eddy currents in metallic objects. The larger the frequency, the larger the floor temperature. The electrical frequency is monitored by way of sensors to prevent overheating. Induction heating is programmable so that only specified areas of the worm shaft will harden.

Frequent tangent at an arbitrary position on both surfaces of the worm wheel

A worm gear is composed of two helical segments with a helix angle equivalent to ninety degrees. This form makes it possible for the worm to rotate with much more than one tooth for every rotation. A worm’s helix angle is normally near to 90 levels and the human body length is reasonably extended in the axial course. A worm equipment with a lead angle g has related homes as a screw gear with a helix angle of ninety degrees.

The axial cross part of a worm equipment is not conventionally trapezoidal. Rather, the linear part of the oblique side is changed by cycloid curves. These curves have a widespread tangent close to the pitch line. The worm wheel is then shaped by equipment chopping, resulting in a equipment with two meshing surfaces. This worm equipment can rotate at high speeds and even now work quietly.

A worm wheel with a cycloid pitch is a a lot more efficient worm gear. It decreases friction in between the worm and the equipment, resulting in greater longevity, improved working efficiency, and diminished noise. This pitch line also helps the worm wheel engage far more evenly and effortlessly. Additionally, it helps prevent interference with their physical appearance. It also tends to make worm wheel and gear engagement smoother.

Calculation of worm shaft deflection

There are a number of techniques for calculating worm shaft deflection, and each and every technique has its possess established of drawbacks. These commonly utilized approaches supply great approximations but are inadequate for identifying the real worm shaft deflection. For instance, these strategies do not account for the geometric modifications to the worm, such as its helical winding of tooth. Additionally, they overestimate the stiffening impact of the gearing. Consequently, efficient slender worm shaft designs require other approaches.

Luckily, several methods exist to determine the greatest worm shaft deflection. These approaches use the finite element technique, and contain boundary problems and parameter calculations. Right here, we search at a pair of techniques. The initial strategy, DIN 3996, calculates the highest worm shaft deflection primarily based on the examination outcomes, whilst the second one particular, AGMA 6022, employs the root diameter of the worm as the equivalent bending diameter.

The 2nd technique focuses on the basic parameters of worm gearing. We will take a nearer look at each and every. We’ll analyze worm gearing enamel and the geometric aspects that affect them. Commonly, the range of worm gearing enamel is 1 to four, but it can be as large as twelve. Picking the teeth need to count on optimization demands, like effectiveness and bodyweight. For example, if a worm gearing wants to be smaller sized than the earlier product, then a modest amount of enamel will suffice.

China best High Efficiency Helical Worm Gear Motor with CE and CCC Certification near me shop

Merchandise Description

Company Profiles

-We are a top equipment motor maker

ZHangZhoug Xihu (West Lake) Dis.hai Reducer is a foremost maker of equipment motor and gearbox.

Given that 1991, we have specialized in producing a extensive selection of gear motor and gear box like:

- helical equipment motor

- helical bevel equipment motor

- parallel shaft helical gear motor

- helical worm gear motor

- hoist drive

- weighty-duty helical gearbox

- hefty-responsibility helical bevel gearbox

- gear motor for car parking program

- sprial bevel gearbox

Solution Description

E sequence equipment motor is blended with helical equipment and worm gear. It is 90° for enter and output shaft.

Mounting situation: footed mounting, flange mounting and shaft mounting and so forth.

Complex data:

Output velocity:.twelve~397rpm

Rated output torque:ten~4200N*m

Motor electrical power: .twelve~22KW

Solution Present

Item Specification

Deal

Plastic bag + wood carton

Certificate

FAQ

Q: Can you print other colours?

Yes. Custom-made coloration can be printed on the gear motor according to your requirements.

Q: Is that manufacturing unit cost?

Sure. We CZPT you all costs are primarily based on factory.